Agrees to acquire Syerston Project from Ivanhoe Mines Group

Agrees to acquire Syerston Project from Ivanhoe Mines Group

Perth, Nov 24, 2014 AEST (ABN Newswire) - Clean TeQ Holdings Limited ( ASX:CLQ) is pleased to announce it has acquired the Syerston Project in central New South Wales from a wholly owned subsidiary of Ivanhoe Mines Ltd (

ASX:CLQ) is pleased to announce it has acquired the Syerston Project in central New South Wales from a wholly owned subsidiary of Ivanhoe Mines Ltd ( TSE:IVN).

TSE:IVN).

The purchase is a significant first step in implementing the Board’s strategy to build Clean TeQ’s metal recovery business by identifying and securing projects which are able to be transformed into world class assets by utilising Clean TeQ’s innovative and disruptive technologies.

Acquisition Structure

Clean TeQ Metals Pty Ltd, a wholly owned subsidiary of Clean TeQ Ltd, has agreed to acquire all the outstanding shares in Ivanplats Holding Company Pty Ltd, the Australian holding vehicle for Ivanhoe Mines Group’s interest in the Syerston Project. As part of the acquisition, Clean TeQ Metals will acquire the following:

- 100% title to the Syerston exploration license and the six mining lease applications underlying the Project;

- Freehold interest in four separate farming properties, comprising 2,884 hectares in total, underlying the mineral title; and

- Water rights owned by the project company.

The consideration for the acquisition will be paid at completion, which is expected in the first quarter of calendar 2015, and comprises:

- A$1.0 million in Clean TeQ scrip, to be satisfied through the issue of shares in Clean TeQ to Ivanhoe Mines, priced at a 5-day VWAP at completion;

- A$100,000, payable in cash at completion; and

- A 2.5% gross royalty on the Project payable to Ivanhoe Mines.

Completion will occur on satisfaction of a number of conditions which are customary in a transaction of this nature, including Clean TeQ shareholder approval. Additionally, Clean TeQ will complete metallurgical test work from drill samples taken from the Project area.

Clean TeQ has also issued Ivanhoe Mines a promissory note with a face value of A$3 million, payable in three years’ time and carrying a zero coupon. The note will enable Clean TeQ to evaluate options for retaining the freehold title in the farming properties as part of a development plan over the next three years. In the event that ownership of the freehold is not deemed critical to the project development plan, it can be sold, with the proceeds used to satisfy redemption of the note.

The Agreement provides an excellent opportunity for both companies, as it allows Ivanhoe to focus on its projects in Africa, while still realising value in the Project through its Clean TeQ shares, the promissory note and future royalties.

Clean TeQ Chairman Sam Riggall said today: ‚ÄúThe deal announced today with Ivanhoe Mines is an important milestone for Clean TeQ and its shareholders. It is based on the simple premise that Clean TeQ‚Äôs suite of ion exchange technologies can unlock significant value in metal extraction and purification processes, whether from primary mine production or industrial process streams. We are particularly excited to have the opportunity to continue our ground-breaking work in scandium recovery, a metal we believe has enormous significance for the next generation of high performance alloys and fuel cells for aerospace, transportation and energy markets. Our significant investment in recent years in scandium recovery technology has positioned us well to be a market leader in this field.‚ÄĚ

Project History

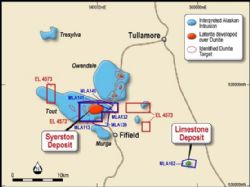

The Syerston Project is located 2km from the regional town of Fifield (350km northwest of Sydney). The Fifield District is noted for its intense magnetic geological anomalism and significant occurrences of minerals containing platinum, nickel, cobalt and scandium.

The district remains the location of Australia’s only historic source of platinum production, with approximately 20,000 ounces of the metal being extracted from deep leads between 1887 and the mid-1960s.

Despite promising indications of platinum mineralization, few companies have succeeded in identifying economic grades of PGM mineralisation.

In 2000, SNC-Lavalin completed a feasibility study for Black Range Minerals Limited, the owner of the Project. The study focused on a variety of development options for a nickel laterite operation and throughout 2002 and 2003 work focused on project financing.

In 2004, Ivanhoe Mines acquired the Project from Black Range Minerals and continued to progress development studies for the resource, focussing principally on extracting nickel and cobalt from the laterite. As part of its studies, it completed an in-fill RC drill program comprising of 174 holes over 6,748 metres. The extensive drill samples were assayed for key minerals, including nickel, cobalt, platinum and scandium.

Throughout the history of the Project, the scandium occurrences in the assays remained little more than a geological curiosity. However, as industrial uses for scandium have grown, so has its importance to the Project.

The Fifield District remains one of the few known locations in the world where scandium occurs naturally in potentially economic concentrations. Grades averaging over 400 ppm have been defined in resources on the boundary of neighbouring license areas.

The extensive assays from historic drill campaigns show the presence of significant scandium grades across the Project area. Recent drilling completed by Ivanhoe Mines in August 2014 supports the historic data, with even higher grades being encountered trending south and east across the property. Clean TeQ intends to complete the drill campaign to define a scandium resource in coming months.

Technology ‚Äď The Key to Unlocking Value in Scandium Extraction

Clean TeQ’s proprietary ion exchange technology has been primarily developed for the extraction and purification of base and strategic metals. While not common in the western world, ion exchange technologies for the recovery of metals have been used extensively and successfully for many decades in the former Soviet Union.

Between 2004 and 2008, the application of Clean TeQ’s technology for metal recovery from lateritic ores was developed in collaboration with BHP Billiton through an A$8 million investment.

Clean TeQ’s unique resin-in-pulp (RIP) process, utilising a combination of continuous ion exchange sorption and desorption processes, was proven to extract and concentrate nickel and cobalt directly from acidic lateritic pulps at a much lower cost than conventional routes.

Following successful completion of piloting for nickel recovery, Clean TeQ has applied its technology across a number of industrial applications. In the past three years, it has worked closely with the titanium dioxide industry to develop a cost-effective alternative to conventional solvent extraction processes to recover scandium from titanium dioxide intermediate process streams.

This work has recently culminated in the delivery of a scandium recovery pilot plant to a large Japanese titanium dioxide producer.

The pilot plant is currently being commissioned.

Data from the pilot plant will be used to confirm the production cost of scandium oxide from this industrial source and allow for multiple process streams to be trialled. Subject to successful piloting and agreement on commercial terms, a review of the options for full scale development in Japan will be undertaken.

Clean TeQ believes that its scandium technology provides a significant capital and operating cost advantage over conventional solvent extraction processes.

While the process for recovery of scandium oxide from primary mine production will have its own specific flow sheet, Clean TeQ believes the foundation technology and ionic extraction and purification chemistry of the process will remain the same.

At Syerston, leaching and extraction work has commenced on samples taken from both historic and recent drill campaigns. The mineralisation is hosted in a weathered lateritic material typically only a few metres below the surface. Therefore, mining of ore is expected to be relatively simple, with the focus on the efficiency of the leaching and extraction steps, in particular acid and reagent consumption and metal recovery.

Following successful laboratory testwork, Clean TeQ intends to deploy its pre-constructed resin-in-pulp pilot plant (Figure 4) in the field to validate the technology and economics. The immediate availability of this plant will allow a fast-tracking of test work while significantly reducing development risk and cost.

About Scandium

Scandium is a transitional metal, often classified as a rare earth element. It has been recognized for many decades as a metal conferring exceptional alloying properties for the production of light-weight, strong sheet and component metals (particularly aluminium). However, its uptake has been severely limited by its relative scarcity in mineable economic concentrations. As one analyst has noted, scandium ‚Äúis devilishly difficult for mother nature to concentrate.‚ÄĚ

All scandium produced in the world today is a by-product from the extraction of other elements, usually uranium, nickel and cobalt. It is usually sold as a high purity oxide (Sc2O3 at 99.9%). There is no primary mine production of scandium anywhere in the world today. The lack of secure supply has led to significant volatility in pricing, with scandium oxide prices ranging between $2,300/kg to $5,200/kg over recent years (Source: QYResearch Scandium Oxide Industry Research Center, 2014).

The absence of reliable, secure and long term production has limited commercial applications of scandium in most countries. This is despite a comprehensive body of research and a large number of patents which identify significant benefits for the use of scandium over other elements. Key growth markets include:

- Strengthened aluminium-scandium alloys for the production of cheaper, lighter and stronger aircraft.

- Scandia stabilized zirconia has a growing market demand for use as a high efficiency electrolyte in solid oxide fuel cells, such as those produced by Bloom Energy.

- High performance athletic equipment, such as aluminium baseball bats, bicycle frames and lacrosse sticks.

- A ‚Äėconditioner‚Äô in mercury vapour lamps to enable light to be emitted that closely resembles sunlight.

In 2010 the European Union identified aluminium-scandium alloys as one of the five most critical emerging technologies in the automotive engineering and aerospace industry (EC Enterprise and Industry Working Group, Critical Raw Materials for the EU, 2010). China has also placed a high strategic priority on securing scandium supply as its rare earths industry is facing significant environmental management issues.

Market Development

The lack of any reliable supply of scandium has been the limiting factor in development of this market. However, this has the potential to change rapidly as scandium from primary mine production is brought on stream and expanded.

Clean TeQ is confident that through the application of its proprietary technology to the Syerston Project it will have the potential to develop the world’s first primary source of scandium oxide production for industries requiring reliable, cost-effective supply of this highly strategic metal. This could be particularly important for the aluminium industry, where low prices, systemic over-capacity in smelting and low growth in new applications could be overcome by a radical re-shaping of the performance characteristics of the metal and its value in use in many new applications.

To view all figures and presentation, please visit:

http://media.abnnewswire.net/media/en/docs/78739-ASX-CLQ-415477.pdf

About Clean TeQ Holdings Limited

Clean TeQ Holdings Limited (ASX:CLQ) is a world leader in water treatment and resource recovery technology and the Australian leader in biological air purification. Clean TeQ develops technologies in-house and partners with leading technology suppliers worldwide.

Clean TeQ Holdings Limited (ASX:CLQ) is a world leader in water treatment and resource recovery technology and the Australian leader in biological air purification. Clean TeQ develops technologies in-house and partners with leading technology suppliers worldwide.

The Company offers a range of business models to potential clients including licensing our technology, building and commissioning complete installations (both transportable and fixed), and building and operating installations in joint ventures, in return for a share of revenues generated through resources recovered. Clean TeQ will also acquire mining assets where its technologies can make exploitation of uneconomic ore bodies or re-processing of tailings profitable.

For more information about Clean TeQ please visit the Company's website

![abnnewswire.com]()

Related Companies

Social Media

Share this Article

ASX:CLQ) is pleased to announce it has acquired the Syerston Project in central New South Wales from a wholly owned subsidiary of Ivanhoe Mines Ltd (

ASX:CLQ) is pleased to announce it has acquired the Syerston Project in central New South Wales from a wholly owned subsidiary of Ivanhoe Mines Ltd ( TSE:IVN).

TSE:IVN). Clean TeQ Holdings Limited (ASX:CLQ) is a world leader in water treatment and resource recovery technology and the Australian leader in biological air purification. Clean TeQ develops technologies in-house and partners with leading technology suppliers worldwide.

Clean TeQ Holdings Limited (ASX:CLQ) is a world leader in water treatment and resource recovery technology and the Australian leader in biological air purification. Clean TeQ develops technologies in-house and partners with leading technology suppliers worldwide.