JORC Update

Sydney, Feb 12, 2024 AEST (ABN Newswire) - Clean lithium developer Lake Resources N.L. ( ASX:LKE) (

ASX:LKE) ( LK1:FRA) (

LK1:FRA) ( LLKKF:OTCMKTS) reports that drilling completed at the Kachi Lithium Brine Project ("Kachi" or the "Project") in Catamarca Province, Argentina continues to intercept lithium bearing brine in sand units favourable to extraction over thick intervals in the southern portion of central resource area.

LLKKF:OTCMKTS) reports that drilling completed at the Kachi Lithium Brine Project ("Kachi" or the "Project") in Catamarca Province, Argentina continues to intercept lithium bearing brine in sand units favourable to extraction over thick intervals in the southern portion of central resource area.

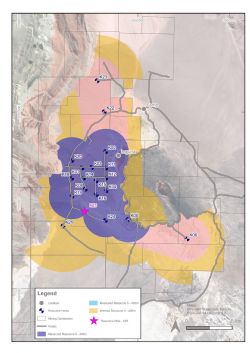

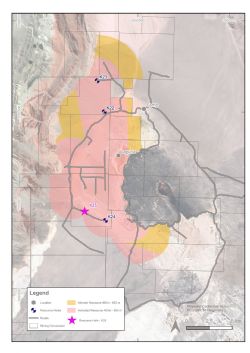

The K25D44 drillhole (Figure 1* and Figure 2*) was not completed in time to be incorporated into the Project's Definitive Feasibility Study (DFS) for Phase One, released in December 2023. However, the results from the drillhole confirm the presence of higher-grade lithium brine south of the central resource area to a depth of more than 600 m. The results further support the positive hydrogeological modelling results that were the basis for the Project Ore Reserve and Definitive Feasibility Study (DFS) submitted in December 2023. The DFS highlights include:

- Total resource is estimated at 10.6 Mt LCE, a globally significant resource.

- 25-year life of mine (LoM) supported by maiden Ore Reserve statement.

- Phase One targets a production of 25,000 tonnes per annum (tpa) over the LoM to meet the growing demand and specifications of the battery market.

- The 25,000 tpa operation recovers only a small fraction of the Measured and Indicated Resource, which allows Lake to study further expansions.

- DLE process tailored to mitigate impact on the local community with minimal disruption to land, freshwater table, and water usage.

- The Project targets production of consistent battery grade lithium carbonate (>99.5% purity) at site without the need for further refining or processing.

- Kachi is targeting first lithium in 2027 with ramp-up to full capacity by the end of 2028, which is forecast to coincide with the start of a prolonged period of structural deficit for battery grade lithium chemicals.

Drillhole results prove the continuity of higher-grade lithium brines, south of the Phase One DFS extraction wellfield design and across a northwest-southeast trending fault that is interpreted to create the escarpment south of the field. The relatively high lithium and favourable geologic materials grades beyond the planned DFS wellfield highlight continued favourable results for a higher capacity wellfield.

"The latest drilling intercept further demonstrates the vertical continuity of the lithium bearing brine to more than 600 metres in clean, fine and medium grained sands conducive to high productive extraction wells." commented Michael Gabora, Director of Geology and Hydrogeology of Lake Resources. He continued, "With an average of 257 mg/L through the production zones, the K25D44 hole continues the trend of intercepting lithium grades that are significantly higher than the 205 mg/L design basis of the DFS".

Continuation of Higher-Grade Lithium Resource Intercepts to the South

The principal objectives of the K25D44 (K25 Platform) drillhole were to:

1) Test the continuity of the lithium resource to the south, outside of the footprint of the salar;

2) Expand the Measured Resource to the south and potentially connect the Measured Resource to previous positive lithium intercepts at K21 (Figure 1*);

3) Complete additional sampling and analysis of the deeper portion of the unconsolidated deposits from about 400 m to more than 600 m depth; and,

4) Validate lithium concentrations used in the area of K25 in the Ore Reserve analysis completed with the calibrated hydrogeologic model.

K25D44 was drilled about 2.25 kilometres southwest of K16D28 (K16 Platform; Figure 1*) and has an average lithium grade of 219 mg/L from 19 samples collected between 40 and 622 m below ground surface (bgs) (Table 1*). All but two samples were collected with single packer configurations generally with a test interval of about 10 to 15 m, although this varied depending on hole conditions. Standard operating procedures are followed with significant development of the test interval, at least 3 borehole volumes (measured from surface to hole bottom), and sampling only occurs once brine is clear and field chemistry parameters are stable and indicative of reservoir fluids.

A standpipe piezometer was installed and screened between 418 to 430 m below ground surface and was developed and sampled via airlifting. Results for the airlift sample are consistent with the packer testing within the same interval, with 275 mg/L measured by SGS and 248 mg/L measured by Alex Stewart laboratory, for an average of 261 mg/L compared to 263.5 mg/L for a packer collected sample from 424 to 430 m below ground surface (see Table 1*).

The fine to medium-grained sand (Figure 3* and Figure 4*) and low frequency of fine-grained layers within the planned production horizons (i.e., approximately 200 m to 600 m) are consistent with drillholes in the central resource area and both stratigraphy and general chemistry support the continuity of the lithium brine resource throughout the southern portion of the field.

As has been observed in the other greater than 600 m deep drillholes completed to-date, the lithium brine continues to a depth of more than 600 m. Lithium concentrations deeper than 400 m averaged more than 250 mg/L, far exceeding the design basis for the DFS (205 mg/L).

The modelled lithium concentration in the Project Ore Reserve8 at K25 was 268 mg/L (200 m to 600 m) within the production horizon. The weighted average of the laboratory results through the same interval (215 m to 622 m) is 271.7 mg/L. This indicates that the modelled values are representative, if not slightly conservative, relative to the measured data in the field at this location. The results of the comparison further build confidence in the lithium resource model used as the basis for lithium distributions within the hydrogeological model and Ore Reserve modelling.

*To view tables and figures, please visit:

https://abnnewswire.net/lnk/UOL27931

About Lake Resources NL

Lake Resources NL (ASX:LKE) (OTCMKTS:LLKKF) is a clean lithium developer utilising state-of-the-art ion exchange extraction technology for production of sustainable, high purity lithium from its flagship Kachi Project in Catamarca Province within the Lithium Triangle in Argentina among three other projects covering 220,000 ha.

Lake Resources NL (ASX:LKE) (OTCMKTS:LLKKF) is a clean lithium developer utilising state-of-the-art ion exchange extraction technology for production of sustainable, high purity lithium from its flagship Kachi Project in Catamarca Province within the Lithium Triangle in Argentina among three other projects covering 220,000 ha.

This ion exchange extraction technology delivers a solution for two rising demands - high purity battery materials to avoid performance issues, and more sustainable, responsibly sourced materials with low carbon footprint and significant ESG benefits.

| ||

|