Tumas Mineral Resource Estimate

Perth, Oct 26, 2016 AEST (ABN Newswire) - Advanced stage uranium explorer Deep Yellow Limited ( ASX:DYL) (

ASX:DYL) ( DYLLF:OTCMKTS) is pleased to provide a clarification to its recently announced JORC 2012 compliant Mineral Resource Estimate ("MRE") for its Tumas Project in Namibia, the MRE remains the same as that reported on 12 October 2016.

DYLLF:OTCMKTS) is pleased to provide a clarification to its recently announced JORC 2012 compliant Mineral Resource Estimate ("MRE") for its Tumas Project in Namibia, the MRE remains the same as that reported on 12 October 2016.

The MRE has a 12% increase in metal content (at the same average grade and cut-off as the previous MRE) and significantly enhanced confidence in the resource with 62% now classified in the Measured Resource Category, 36% in Indicated and the remaining 2% in the Inferred Resource Category.

Tumas Project Mineral Resource Estimate Summary

The Tumas Uranium mineralisation is of the Calcrete type. The uranium mineralisation occurs in conjunction with calcium carbonate precipitations in sediment filled palaeovalleys. Uranium is the only economically extractable metal in this type of mineralisation. Uranium minerals mainly include uranium vanadates. The geology of the mineralisation is well understood having been explored over a number of years.

Data used in the mineral resource estimate is based on a combination of down hole radiometric gamma logging, XRF and ICP-MS assays of RC drill chips as well as lead block scintillometer measurements. Down hole gamma readings were taken at 5 cm intervals and converted into equivalent Uranium values (eU3O8) before being combined to 1 meter intervals. Geochemical assays were derived from 1 meter RC-drilling intervals, which were split to 1 to 4 kg samples by riffle or cone splitters. 90 gram were further pulverised for use in XRF analysis. Same samples were assayed as well for U3O8 by ICP-MS method to confirm the XRF results. Numerous 1 meter samples from Tumas 2 were estimated both via XRF and lead-block scintillometer measurements. Down hole gamma logging defined eU3O8 values were given preference for the resource estimation.

Drilling for the project was based on RC methods only. Drilling achieved recoveries around 90%. All drill chips were logged geologically and added to the database.

Zones 1 and 2 were drill-tested in the period 2008 to 2010 with a total of 4,555 reverse circulation (RC) holes being drilled by DYL's wholly owned Namibian operating subsidiary Reptile Uranium Namibia Pty Ltd ("RUN") for a total of 85,092 metres of drilling.

The generally east-west striking Zone 1 mineralisation was drilled on a consistent, staggered 50 x 50 metre pattern giving a spacing along strike of approximately 100 metres between drill holes. The north-south trending Zone 2 mineralisation was sampled on a 50 x 50 metre square grid with some infilling to a 25 x 50 metre pattern generally along the margins of the mineralised zones.

The mineralisation domains used for the current study were interpreted to capture continuous zones of mineralisation above 50 ppm U3O8. The mineralisation contained in Zones 1 and 2 included in this MRE has a combined strike length of approximately 16 kilometres with an average width of around 400 metres and extends to a maximum depth of 47 metres.

The mineral resource was estimated by Multiple Indicator Kriging (MIK) with block support corrections reflecting open cut mining selectivity. Possible open cut mining scenarios considered 1, 2 and 3 meter mining bench heights. Cut off grades included 100, 150 and 200 ppm U3O8. The estimation of an Exploration Target for the Tumas 3 zone used the same type of data and methods as the Tumas 1 and 2 zone resource estimate.

The MRE for the Tumas 1 and 2 zones is presented in Table 1 (see the link below) at a range of U3O8 cut-off grades whilst the previous (JORC 2004) MRE is shown in Table 2 (see the link below). Primarily, the change in resource size has been driven by an increase in the density assumption which was made possible by the recent work in that area.

The decision was made at this stage to maintain the 200 ppm U3O8 cut-off for the preferred resource however the Company believes that the use of Marenica's U-pgrade(TM) process at Tumas will likely enable a lower cutoff grade resulting in a larger project resource. Note that the figures in the table (see the link below) are rounded to reflect the precision of estimates and may exhibit rounding errors.

Background Information on the Tumas Mineral Resource Estimate

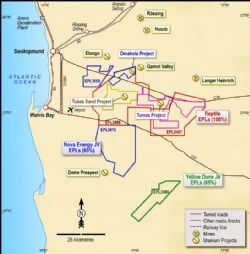

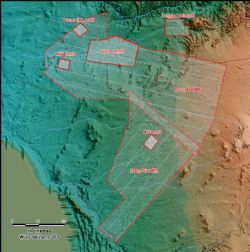

The Tumas palaeochannel straddles DYL's two wholly owned exclusive prospecting licences ("EPLs") 3496 and 3497 and is divided into three zones (See Figures 1 and 2 in the link below). Zones 1 and 2 contain the new mineral resource whilst Zone 3 contains the exploration target. Prior to committing to the Marenica testwork the Company conducted a comprehensive review of the geological potential of Tumas in 2014 and 2015 and concluded that the palaeochannel had extensive upside potential.

During that period an infill drilling program (See Figure 3 in the link below) was completed within Zone 1 and a sophisticated geophysical modelling exercise covering both EPLs was completed which provided confidence in the Tumas deposit and its extended palaeochannel. (See ASX release dated 16 July 2015 titled "Enhanced Palaeochannel Prospectivity" for more information.)

Also, bulk samples were excavated from the infill drilling area in December 2015 and January 2016 and sent to Perth to conduct the first phase of U-pgrade(TM) metallurgical testwork. This was successfully completed at the end of June 2016.

Tumas mineralisation occurs as secondary carnotite enrichment of variably calcretised palaeochannel and sheetwash sediments and adjacent weathered bedrock.

Summary of Recent Work Contributing to the MRE

Infill Drill Program

The 90-hole close-spaced infill program completed in December 2014 (at 12.5m x 12.5m centres for approximately 1,450m in total) confirmed a continuously mineralised north-south front over 160 metres and 50 metres wide (east-west) which was entirely consistent with previous drilling results. This was highly encouraging as the previous resource model was based on the results of earlier drill programs that typically had wider spacing. In the 2014 program the grades obtained by downhole gamma logging and validated by ICP-MS assay were a good match in tenor with the historical results and the previous mineral resource model.

Mineralisation within the infill drill area was found to be confined to the channel sediments only and not in the bedrock which will make mining simpler and improves the prospects for successful beneficiation. Only limited amounts of internal dilution were found to be present which further enhances the level of confidence one can expect in regard to beneficiation.

The topography of the base of the palaeochannel was confirmed to be gently undulating and appears to have no influence on the 'blanket' mineralisation and not to be a significant influence on the uranium grade, thickness or mineralisation. The saucer-like geometry of some of the channel margins indicates that mineralisation may be present even in areas with as little as 2 metres of channel fill. This can in future be delineated by detailed mapping of the channel margins.

At the same time as the infill drill program an internal study predicted the calcrete-hosted tonnes of uranium per lineal kilometre that might be present along the Tumas drainage channel. For this prediction certain assumptions pertaining to the consistency of the grade and thickness of the mineralisation within the channels had to be made via interpolation from historical more widely spaced drilling. The evidence from the drilling supported these assumptions, albeit over a limited area and allowed DYL to predict a range of between 1.8 and 3Mlbs U3O8 per kilometre.

The study assisted with the confirmation of the exploration target for Zone 3 even when the figures are discounted by up to 50% to build in some conservatism in recognition of the relatively low level of definition across that part of the palaeochannel system.

Importantly, the infill drilling program also allowed a reassessment of density in the palaeochannel which seemed to have been underreported in previous work. Probing during the infill drilling program confirmed this suspicion as density measurements encountered were in ranges varying from 1.81 for loose, sandy gypcrete to 2.64 - 2.71 for massive calcrete. With the bulk of the measurements between 2.26 - 2.41 an average density of 2.35 was adopted for this MRE compared to the previous average of 2.1.

Resource Potentials Geophysical Interpretation

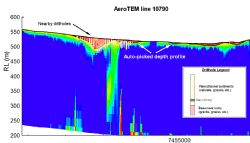

In 2008 an extensive AeroTEM helicopter electromagnetic ("HEM") survey (see Figure 4 in the link below) was flown for DYL by Aeroquest Ltd of Canada covering EPLs 3496 and 3497. A total of 4,107 survey line kilometres were flown at a relatively broad 500m line spacing.

The HEM survey area was known to be prospective for uranium mineralisation located in near-surface palaeochannels which may be expected to have a positive conductivity contrast with underlying fresh basement bedrock. Palaeochannel conductivity varies based on a number of factors including clay type and content, porosity, permeability and most importantly the salinity of the ground water. A saline palaeochannel would be expected to be much more conductive and produce a stronger electromagnetic signal compared to one containing fresh water.

Resource Potentials was commissioned in 2015 to convert the AeroTEM EM time channel data to conductivitydepth values and then run an auto-picking processing routine on the conductivity-depth data to determine the thickness of conductive cover above fresh bedrock "basement", and produce a set of georeferenced data products.

Selected AeroTEM survey flight lines were initially processed using the industry standard conductivity-depth imaging ("CDI") software EMFlow but did not produce reliable results. An alternative software code, Layered Earth Inversion ("LEI") recently released by Geoscience Australia was trialled and proved to be much more robust. The complete AeroTEM dataset was then processed using the LEI program to generate conductivitydepth values for all flight lines.

The auto depth-picking routine process was then run on the LEI data along each flight line to calculate the thickness of conductive cover, as represented by the conductivity variation in the LEI sections. A suite of georeferenced images was created, together with a range of data products encapsulating the LEI and auto depth-picking results; such as grid surfaces and images of the fresh rock depth, conductivity depth slices and other processed EM data. LEI conductivity sections and EM decay multiplots were produced for each AeroTEM survey flight line to display the final depth of conductive cover thickness along each survey line.

Depth to fresh bedrock from drilling was also gridded and imaged for selected prospect areas, and compared to the LEI results. The calculated conductive cover thickness results were compared to drilling data supplied by DYL over the known palaeochannels hosting uranium mineralisation. In general, the calculated conductive cover thickness broadly agreed with the palaeochannel thickness determined from drilling (see Figure 5 in the link below). It should be noted that gridded images and resulting contours of the calculated conductive cover thickness model may only broadly represent the palaeochannels, because of the very broad 500m flight line spacing for this survey; i.e. modelling of the palaeochannels is limited by the survey flight line orientational resolution.

The drillholes shown in Figure 5 (see the link below) appear slightly vertically offset because the "envelope" of displayed drillholes is 50 m each side of the survey line. Therefore, their collar elevations are likely to be slightly different to the survey line elevation given the slope of the ground on either side of the profile and the 3D geometry of meandering palaeochannels. Despite this, the logged bedrock lithologies generally reflect the same shape of the LEI auto-picked depth-to-basement well. Furthermore, the HEM results identified new zones of palaeochannel deposits that have not been drill tested and will form the basis for future direct drill targeting.

The palaeochannel depth map in this area can now be used to interpret uranium potential of undrilled areas and help to plan focussed drilling on new targets; despite the wide 500m survey line spacing. The most encouraging result of this interpretation is the confirmation of the lateral extent and potential depth of the palaeochannel system across the two EPLs. The palaeochannel system was independently confirmed to be well over 100 kilometres in extent and in places reaches depths of 130 metres.

Marenica U-pgrade(TM) Metallurgical Testwork Program

The U-pgrade(TM) metallurgical testwork program was successfully completed at the end of June 2016 (see DYL ASX releases dated 20 May, 31 May and 1 July 2016). The success of the program gave DYL the confidence to progress with the next phases of the Tumas Project and to execute a Technology Licencing Agreement with Marenica Energy Limited for the right to use its proprietary beneficiation process.

The testwork was conducted on a bulk sample that was excavated from the Tumas deposit late in 2015 and early 2016 (see Figures 6 and 7 in the link below). Apart from enabling the bulk sample to be excavated the trench also used for a detailed channel sampling exercise which allowed DYL to compare channel sample grades to those of the infill drilling program.

The grades compared favourably and are shown in Figure 8 (see the link below). Of particular interest was an improved understanding of the higher grades that were contained in the higher sulphate containing gypcrete layer compared to the underlying calcrete mineralisation. Particle size distribution tests were also conducted for metallurgical testwork purposes.

The U-pgrade(TM) metallurgical testwork program showed that more than 95% of the carbonate minerals in the Tumas bulk sample could be removed with a loss of less than 5% of the uranium whilst the de-sliming step rejected ~27% of the mass as fine particulate material. These results demonstrated that the critical carbonate and de-slime removal steps of the U-pgrade(TM) process work on the bulk samples provided and that it was effective in treating both a low and a medium sulphate sample. As a result DYL and Marenica concluded that the application of the U-pgrade(TM) process would enable a significant reduction in the mass being handled with only a minor loss of uranium, allowing the upgrading of uranium into a low mass concentrate at the Tumas Project.

In summary the results indicated that a concentrate containing less than 3% of the ore feed mass grading between 10,000 and 15,000 ppm U3O8 and containing greater than 82% of the uranium could be generated from the Tumas bulk samples by the U-pgrade(TM) process.

Summary of 2008-2010 Drilling Campaigns

Tumas Zones 1 and 2

Zones 1 and 2 were drill-tested in the period 2008 to 2010 with a total of 4,555 reverse circulation (RC) holes being drilled by DYL's wholly owned Namibian operating subsidiary Reptile Uranium Namibia Pty Ltd ("RUN") for a total of 85,092 metres of drilling (see Table 3 in the link below).

The generally east-west striking Zone 1 mineralisation was drilled on a consistent, staggered 50 x 50 metre pattern giving a spacing along strike of approximately 100 metres between drill holes. The north-south trending Zone 2 mineralisation was sampled on a 50 x 50 metre square grid with some infilling to a 25 x 50 metre pattern generally along the margins of the mineralised zones.

The mineralisation domains used for the current study were interpreted to capture continuous zones of mineralisation above 50 ppm U3O8. The mineralisation contained in Zones 1 and 2 included in this MRE has a combined strike length of approximately 16 kilometres with an average width of around 400 metres and extends to a maximum depth of 47 metres.

Data available for the Tumas drilling includes in-rod and open-hole gamma logging, XRF assay results and scintillometer measurements from samples placed in lead shielded box as well as more recently ICP-MS . The current estimates are based primarily on one-metre down-hole composited U3O8 grades derived from gamma logging. For the composite dataset compiled for the current estimates, grades derived from gamma logging were assigned a higher priority than XRF assay results, and scintillometer derived grades were used for intervals without logging or XRF results.

Tumas Zones 1 and 2 resources were estimated by Multiple Indicator Kriging (MIK) with block support correction, and reflect open-cut mining selectivity. As requested by RUN, the estimates assume one metre mining bench heights with 5 x 5 metre grade control sampling. Estimates for mineralisation tested by consistently 50 x 50 metre spaced drilling are classified as Indicated and all other estimates are classified as Inferred.

Tumas Zone 3

In addition to the Tumas 1 and 2 resource estimates presented in Table 1 (see the link below) the current study included construction of a MIK model for the Tumas 3 area. This modelling suggests that, at a cut-off grade of 200 ppm U3O8, the Tumas 3 area has the potential to host an exploration target of approximately 20 to 30 million tonnes at a grade of approximately 200 to 250 ppm U3O8 which would more than double the Tumas Project Mineral Resource Estimate. This potential mineralisation is based on broadly spaced drilling (see Table 4 in the link below) and has had insufficient exploration to define a Mineral Resource, and the estimates of tonnage are conceptual in nature. It is uncertain that further drilling will convert any of the exploration potential to a Mineral Resource.

Drilling included 50 metre spaced holes along sets of east-west and north-south traverses separated by 600 to 2,000 metres, and some locally tight-spaced infill drilling. When combined with geophysical survey results, this wide-spaced sampling provides an indication of the extent and general orientation of mineralisation in Tumas Zone 3, however the mineralisation is too poorly defined at this stage for inclusion in resource estimates.

Interpretation of the Tumas 3 mineralisation is further hindered by the number of drill holes without gamma logging, XRF or scintillometer measurements which is notably higher than for the other Tumas areas. These un-sampled holes include holes surrounded by mineralised drilling, with around 10% of drill holes within the plan-view extents of the mineralised domain interpreted for the study having no grade data.

To view the announcement, please visit:

http://abnnewswire.net/lnk/I956K0B6

About Deep Yellow Limited

Deep Yellow Limited (ASX:DYL) (OTCMKTS:DYLLF) is successfully progressing a dual-pillar growth strategy to establish a globally diversified, Tier-1 uranium company to produce 10+Mlb p.a.

Deep Yellow Limited (ASX:DYL) (OTCMKTS:DYLLF) is successfully progressing a dual-pillar growth strategy to establish a globally diversified, Tier-1 uranium company to produce 10+Mlb p.a.

The Company's portfolio contains the largest uranium resource base of any ASX-listed company and its projects provide geographic and development diversity. Deep Yellow is the only ASX company with two advanced projects - flagship Tumas, Namibia (Final Investment Decision expected in 1H/CY24) and MRP, Western Australia (advancing through revised DFS), both located in Tier-1 uranium jurisdictions.

Deep Yellow is well-positioned for further growth through development of its highly prospective exploration portfolio - ARP, Northern Territory and Omahola, Namibia with ongoing M&A focused on high-quality assets should opportunities arise that best fit the Company's strategy.

Led by a best-in-class team, who are proven uranium mine builders and operators, the Company is advancing its growth strategy at a time when the need for nuclear energy is becoming the only viable option in the mid-to-long term to provide baseload power supply and achieve zero emission targets.

Importantly, Deep Yellow is on track to becoming a reliable and long-term uranium producer, able to provide production optionality, security of supply and geographic diversity.

| ||

|