Lewis Ponds Metallurgical Test Work Produces High-Grade Concentrates

Perth, Nov 26, 2018 AEST (ABN Newswire) - Ardea Resources Ltd ( ASX:ARL) (

ASX:ARL) ( ARRRF:OTCMKTS) announces results of metallurgical test work show excellent recovery of base and precious metals into two concentrate streams.

ARRRF:OTCMKTS) announces results of metallurgical test work show excellent recovery of base and precious metals into two concentrate streams.

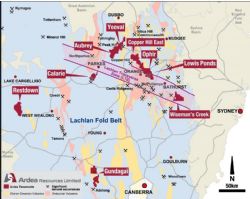

- Lewis Ponds is a zinc-gold-silver-lead-copper deposit in the prospective Lachlan Fold Belt of NSW

- It is viewed as a bulk-tonnage base and precious metal opportunity, amenable to simple metallurgical gravity and flotation processing

- Metallurgical test work comprising Dense Media Separation then flotation has produced:

o Clean zinc concentrate - over 66 % contained zinc

o Cu-Pb-Ag-Au concentrate containing 1,619 g/t silver, 17.6 g/t gold, 4.78 % copper, and 30.3 % lead

o High recovered silver grades are consistent with Lewis Ponds being a silver mine in the late 1800s

o Results show excellent recovery of payable metals and fast flotation kinetics

- Results for both concentrates are first-pass and are expected to benefit from further refinement as studies progress

In parallel to work on the Goongarrie Nickel Cobalt Project, metallurgical test work from the Lewis Ponds Zinc-Gold-Silver-Lead--Copper Project near Orange, NSW, indicates that two high-grade concentrates can be produced using simple gravity and flotation treatment processes.

The Ardea corporate strategy is to continue to advance Goongarrie and accelerate exploration on the prospective gold and nickel sulphide targets in its extensive 5,484km2 land holding in Western Australia.

To focus our efforts and create additional value for Ardea shareholders, the company will seek to crystallise value through a spin out or divestment of its NSW mineral assets in the next twelve months. A resource estimate is underway for Lewis Ponds and the Company is currently reviewing the results of promising metallurgical work which have been completed during 2018. Exploration work is continuing on the Company's NSW tenements notably within the highly prospective Lachlan Transverse Zone (LTZ).

Lewis Ponds metallurgical test results

Lewis Ponds is a zinc-gold-silver-lead-copper deposit in the Lachlan Fold Belt of NSW. Metallurgical test work shows excellent recovery of metals in concentrates through the application of simple conventional metallurgical techniques. Test work completed shows that two concentrates, a zinc concentrate and a copper-lead-precious metal concentrate (Cu-Pb-Ag-Au concentrate, i.e. copper, lead, silver, and gold concentrate) can be produced.

Some notes on the concentrates produced:

- The Zn concentrate contains around 66% zinc (in zinc sulphide), indicating a pure product.

- The Cu-Pb-Ag-Au concentrate contains:

o 1,619 g/t silver (or ~52 oz/t silver)

o 17.6 g/t gold (over 0.5 oz/t gold)

o 30.3 % lead

o 4.78 % copper

- Both concentrates are expected to be eminently saleable with mixed concentrates with high precious metal content readily sought in China

- Results for both concentrates are first-pass and are expected to benefit from further refinement as studies progress.

On an operating scale, the processes used in test work are generally "off-the-shelf" and inexpensive to implement, though this is yet to be modelled for Lewis Ponds.

The findings of this metallurgical study are a significant milestone on the path to development at Lewis Ponds. Further refinement and assessment of the processes will be required, but will now be coming off a very solid base established by this test work.

Test work details and findings

Lewis Ponds mineralisation

Fine-grained banded sulphide mineralisation at Lewis Ponds (1, 2 & 3) contains appreciable amounts of zinc, gold, silver, lead and copper. Sulphide minerals are typical of the large deposits of the Lachlan Fold Belt of NSW, comprising pyrite, sphalerite, galena and chalcopyrite. Non-sulphide gangue minerals are also unremarkable, comprising quartz, feldspars, chlorite, micas, and carbonates.

An important finding is that no secondary sulphide phases or metal oxides were found, greatly simplifying processing of potential ore.

Grain sizes are varied with fine galena (0.03 mm) associated with coarser chalcopyrite and pyrite (0.07 mm), and coarser still sphalerite (0.10 mm) as recrystallised grains within the foliation in "pressure-shadow" positions.

Phase 1 - Ore preparation using DMS

An initial phase of Dense Media Separation (DMS) has the potential to greatly upgrade the economics of the deposit for minimal investment. A prerequisite for DMS, present at Lewis Ponds, is a contrast in density between heavier ore minerals (i.e. metal sulphides) and lighter gangue or waste minerals (silicates and carbonates).

At Lewis Ponds, the studies found that at a 12.5 mm crush size, 94 % of sulphide and precious metal content can be recovered with the rejection 25 % of the mass. This corresponds to a 1.25 upgrade factor.

The process is generally inexpensive to implement, being a form of gravity separation conducted at relatively coarse crush size. It is used to pre-concentrate run-of-mine ore by the rejection of a low grade, low density fraction. Application of a successful DMS circuit can allow a combination of lower ore cut-off grade in the mine and/or a higher mill feed grade, potentially providing enhanced project economics.

Phase 2 - Flotation

The second phase of the process involves a conventional crush and float circuit to produce concentrates. The initial aim has been to produce two distinct products:

- a mixed copper, lead, silver and gold concentrate marketed for its high precious metals content;

- a clean zinc concentrate.

A total of 20 tests were conducted to establish the initial flotation flowsheet and reagent regime. Work shows that good flotation performance combined with fast flotation kinetics is very achievable from a relatively simple selective flowsheet.

The results of the test work are summarised in Table 1 (see link below). With these metallurgical results in mind, work is underway on the redefinition of a base and precious metal resource update at Lewis Ponds.

Zinc concentrate

The zinc concentrate constitutes around 3.4 % of the ore feed by mass (see Table 1 in link below). It contains around 66% zinc (predominantly in the zinc sulphide, sphalerite), indicating a pure product. Iron has been minimised, and in the concentrate is likely partially within the sphalerite crystal structure, but also partly in associated pyrite.

Recovery of around 87 % of the contained metal from the feed using these techniques is excellent. When including the zinc content of the Cu-Pb-Ag-Au concentrate, zinc recoveries exceed 90 %.

Copper-Lead-Precious Metal concentrate

The Cu-Pb-Ag-Au concentrate represents only 2 % of the ore feed by mass. Both lead and copper are strongly fractionated into this concentrate (by 35 times and by 32 times respectively). Lead recoveries of around 73% of the contained metal are good, better than the ~64 % copper recoveries. These represent opportunities for future improvement.

Gold and silver overwhelmingly report to the Cu-Pb-Ag-Au concentrate (~37 times and 29 times concentrated respectively) with high values of 1,619 g/t silver and 17.6 g/t gold. Recovery percentages once again present refinement opportunities. Both precious metals show an affiliation with the fine-grained lead sulphide galena. Separate testing of pyrite concentrates shows that they are very low in gold in this sample set.

Tails

The final tails, which constitute 94.6 % of the mass of the feed, show significant depletion of all metals of interest, along with little change in waste iron contents (see Figure 5 in link below). Of these, zinc extraction has been the most efficient, with over 90 % of the zinc recovered.

Further enhancements to the process

Refinement of the defined processes will continue, with several opportunities presenting.

The next phase of DMS test work will use a larger composite sample with the separation made in a pilot scale dense medial cyclone (as would be used in a full-scale plant design) instead of the small-scale bench sink-float Heavy Liquid Separation (HLS) test work used in this initial program. It was planned that the -1mm fines, which is not fed to the DM cyclones, will be the subject of reflux classifier test work to determine its potential beneficiation potential.

Further flotation development test work is required, particularly in optimising the mixed Cu-Pb-Ag-Au circuit (galena liberation and depressant optimisation for pyrite, sphalerite and non-sulphide gangue). Further improvements are expected through pyrite and sphalerite rejection from the mixed Cu-Pb-Ag-Au concentrate with a consequent increase in the lead grade of the mixed Cu-Pb-Ag-Au concentrate. Extraction of sphalerite from the Cu-Pb-Ag-Au concentrate and incorporation into the Zn concentrate would result in increased payable zinc recoveries.

About the Lewis Ponds deposit

Lewis Ponds is a zinc-gold-silver-lead-copper deposit in the Lachlan Fold Belt of NSW (see Figure 6 in link below). The belt is host to numerous major bulk tonnage gold and base metal mines. Of particular note is that the major deposits at Northparkes and Cadia are hosted within or adjacent to the Lachlan Transverse Zone (LTZ), a west-northwest trending lineament that is thought to represent a fundamental crustal weakness that corresponds to major mineralised centres. Several of Ardea's projects, including notably Lewis Ponds, are located within the LTZ.

Previously, Lewis Ponds has been explored as a high-grade underground deposit, with a historic resource of 6.6Mt at 1.5g/t Au, 69g/t Ag and 2.4% Zn1 estimated (refer Prospectus Table 3.2 for full description of resource status). This resource is presently being re-estimated for a bulk tonnage mining operation.

As a potential Massive Sulphide underground operation, the published Lewis Ponds resource (refer below) was calculated at a 3% zinc equivalent cut-off. This is opposed to Ardea's 1.5% zinc equivalent cut-off for an envisaged open pit Stringer Sulphide mining operation. The Ardea concept is consistent with bulk tonnage operations in the central Lachlan Fold Belt which are all low grade, bulk excavation-based (see Table 2 in link below). Both Cadia and Northparkes produce sulphide concentrates with precious metal credits, whereas Cowal and the undeveloped McPhillamys deposit utilise (or propose to utilise) a carbon-in-leach (CIL) flowsheet. In terms of metal value (i.e. zinc and gold equivalent values), the mineralised zones intercepted in Ardea diamond core holes ALD0003 and ALD0004 match or exceed those of the major Lachlan Fold Belt operations (see Table 2 in link below).

These results justify Ardea's updated Exploration Target for the Lewis Ponds deposit, estimated at 15-25 Mt at 2.2-3.7 % ZnEq or 1.2-2.0 g/t AuEq2 (Heron Resources announcement, "Ardea Project Update" dated 6 January 2017).

To view tables and figures, please visit:

http://abnnewswire.net/lnk/YC9WVSHC

About Ardea Resources Ltd

Ardea Resources Ltd (ASX:ARL) (OTCMKTS:ARRRF) (FRA:A91) is an ASX listed resources company, with 100% controlled Australian based projects, prioritising a three-pronged value creation strategy which is:

Ardea Resources Ltd (ASX:ARL) (OTCMKTS:ARRRF) (FRA:A91) is an ASX listed resources company, with 100% controlled Australian based projects, prioritising a three-pronged value creation strategy which is:

- development of the Goongarrie Nickel Cobalt Project, which is part of the Kalgoorlie Nickel Project, a globally significant series of nickel-cobalt deposits which host the largest nickel-cobalt resource in the developed world, coincidentally located as a cover sequence overlying fertile orogenic gold targets;

- advanced-stage exploration at WA gold and nickel sulphide targets within the Eastern Goldfields world-class nickel-gold province; and

- the demerger of the NSW gold and base metal assets with planned in-specie share distribution, with projects located within the Lachlan Fold Belt world-class gold-copper province.

| ||

|