ALCORE Reaches 1st Milestone - December Production on Target

Sydney, Oct 15, 2018 AEST (ABN Newswire) - Australian Bauxite Limited (ABx)'s ( ASX:ABX) wholly-owned subsidiary, ALCORE Limited has completed the design phase of the Stage 1 project on schedule and has commenced acquiring the equipment for production to commence before year-end, ahead of schedule.

ASX:ABX) wholly-owned subsidiary, ALCORE Limited has completed the design phase of the Stage 1 project on schedule and has commenced acquiring the equipment for production to commence before year-end, ahead of schedule.

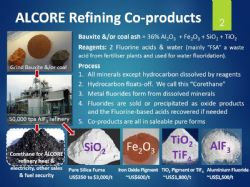

- ALCORE's patent (pending) application technology is designed to refine raw bauxite to produce Aluminium Fluoride (AlF3) and other valuable co-products - see Figures 1 & 2(see link below). AlF3 is a key electrolyte ingredient in the production of aluminium metal at aluminium smelters.

- Global demand for AlF3 and associated co-products continues to increase as aluminium smelter production increases and the use of AlF3 in lithium ion batteries increases.

- Site construction works for Stage 1 of the ALCORE project commenced on 1 July as planned at ALCORE's pre-approved Pilot Plant site in Berkeley Vale, Central Coast NSW.

- Stage 1 is designed to produce AlF3 test samples for pre-qualified aluminium smelter customers & then produce Corethane, which is pure hydrocarbon powder refined from low-value coals.

- Corethane has been used to provide thermal and electrical power. It has been used as a gas-substitute to fuel a standard large gas turbine for 14 months and achieve accreditation as a turbine fuel to generate electricity with very low CO2 emissions.

- Corethane has also been used as a diesel substitute for fuel security purposes and is ideally suited for use as a sulphur-free bunker fuel.

- Corethane also has industrial applications and several potential customers have already requested test samples for their industrial plants.

- Graphite refining to a very high purity for use in high-efficiency batteries will also be tested.

- Discussions continue with governments, agencies and major companies in the aluminium industry.

ABx CEO, Ian Levy commented: "ABxs subsidiary ALCORE is sufficiently funded to deliver Stage 1 of the ALCORE project, thanks to strong support from seed capital investors. ALCORE's powerful new bauxite refining technology can lead to Australia's first production of AlF3 products to provide security of supply for Australasian aluminium smelters. ALCORE Limited is expected to unlock considerable value for ALCORE and ABX shareholders in the short and medium term.

"In addition to Corethane for energy and fuel security, ALCORE Technology will be tested to produce valuable co-products including silica fume for the cement industry that ABx already supplies cementgrade bauxite, as well as ultra-pure AlF3 for Lithium-ion batteries, iron oxide pigments and titanium oxide pigments. Further potential exists for developing ultra-pure products such as high purity alumina ("HPA") for the manufacture of scratch-resistant sapphire glass for phones and computer screens.

"ABx is also pressing ahead with its three core bauxite projects; the Tasmanian mine, the large Binjour Project in central QLD and the Penrose refractory bauxite project 90km inland of Port Kembla NSW. Planning is underway for trial mining and processing testwork at the Binjour Project."

About ALCORE Limited

Australian Bauxite Limited (ABx) has incorporated ALCORE Limited as a wholly-owned subsidiary to fund and manage the ALCORE Project, to lead to the construction of an ALCORE Production Plant to produce Aluminium Fluoride (AlF3) and valuable co-products, using patent (pending) new technology. The ALCORE Technology is designed to convert low grade bauxite worth $50 per tonne into a suite of valuable products worth more than $800 per tonne. Site construction works for Stage 1 of the ALCORE project commenced on 1 July as planned at ALCORE's pre-approved Pilot Plant site in Berkeley Vale, Central Coast NSW.

Stage 1 is designed to produce AlF3 test samples for pre-qualified aluminium smelter customers & then produce Corethane, which is pure hydrocarbon powder refined from low-value coals and has been used to provide thermal and electrical power with low CO2 emissions when used as a gas-substitute to fuel large gas turbine. Corethane has also been used as a diesel substitute for fuel security purposes and is ideally suited for use as a sulphur-free bunker fuel.

To view figures, please visit:

http://abnnewswire.net/lnk/D6NFM2HG

About ABx Group Limited

ABx Group Limited (ABx) (ASX:ABX) has its first bauxite mine in Tasmania & controls the Eastern Australian Bauxite Province. ABx's 11 bauxite tenements in Queensland, New South Wales & Tasmania totalling 662 km2 are all 100% owned, unencumbered & free of third-party royalties. ABx's bauxite is gibbsite trihydrate (THA) bauxite that can be processed into alumina at low temperature.

ABx Group Limited (ABx) (ASX:ABX) has its first bauxite mine in Tasmania & controls the Eastern Australian Bauxite Province. ABx's 11 bauxite tenements in Queensland, New South Wales & Tasmania totalling 662 km2 are all 100% owned, unencumbered & free of third-party royalties. ABx's bauxite is gibbsite trihydrate (THA) bauxite that can be processed into alumina at low temperature.

ABx has committed a large proportion of its expenditure into Research and Development to find ways to capitalise on the main strengths of its bauxite type which is very clean, free of all deleterious elements and partitioned into layers, nodules, particles and grains of different qualities that can be separated into different product streams using physical, chemical and geophysical methods.

ABx has declared large Mineral Resources in northern NSW, southern NSW, Binjour in central QLD & in northern Tasmania.

ABx's first mine commenced at Bald Hill near Campbell Town, Tasmania in December 2014 - the first new Australian bauxite mine for more than 35 years.

ABx aspires to identify large bauxite resources in the Eastern Australian Bauxite Province and has created significant bauxite development projects in 3 states, Queensland, New South Wales and Tasmania. Its bauxite deposits are favourably located for direct shipping of bauxite to both local and export customers.

ABx endorses best practices on agricultural land, strives to leave land and environment better than we find it. We only operate where welcomed.

| ||

|