Quarterly Activities and Cashflow Report - March 2014

Brisbane, April 30, 2014 AEST (ABN Newswire) - Orocobre Limited ( ASX:ORE) (

ASX:ORE) ( TSE:ORL) (

TSE:ORL) ( OROCF:OTCMKTS) provides the quarterly activities and cashflow report for period ending March 2014.

OROCF:OTCMKTS) provides the quarterly activities and cashflow report for period ending March 2014.

Highlights

Olaroz Lithium-Potash-Boron Project:

- Project construction is approximately 85% physically complete with significant milestones achieved.

- A total of approximately US$194 m has been spent or committed via executed contracts on the construction project to date.

- Construction is projected to be completed on budget with first production at the end of August 2014.

Borax Argentina

- Projected to finish the year on or above budget.

- The project to relocate the borax chemical plant from its current location in Campo Quijano (close to the city of Salta) to the Tincalayu mine continues to progress and is expected to be completed on schedule and within budget. The relocation and commissioning was planned to be completed by the end of June 2014 but may now be completed ahead of schedule.

- The Porvenir Historical Estimate has been upgraded to a Measured and Indicated JORC compliant resource. A Measured and Indicated resource of 6.9 million tonnes of 14.9 % B2O3 is estimated at a 9% B2O3 cut-off, the economic cut-off for processing of the mineralisation at a potential new boric acid plant at Olacapato.

- A prefeasibility study into the construction of a boric acid plant at Olacapato in Salta Province, Argentina with a production capacity of 25,000 tonnes per annum of boric acid has been completed. The Project has strong fundamentals with a healthy after tax internal rate of return of 24% based on modeled project life of 20 years underpinned by a resource base of 1.02 million tonnes B2O3.

Corporate

- Cash Position of A$28.7m at the end of the quarter excluding funds in Olaroz Lithium Project companies.

- SAP has been implemented at Borax Argentina.

Olaroz Lithium-Potash-Boron Project

The Olaroz Project is Orocobre's flagship project located in Jujuy province of Argentina. Together with partners, Toyota Tsusho Corporation ("TTC") and Jujuy Energia y Mineria Sociedad del Estado ("JEMSE"), Orocobre is building the first large scale "green fields" lithium brine project in approximately 20 years at a capital cost of US$229.1m and will have a design capacity of 17,500tpa of battery grade lithium carbonate. The Olaroz Project joint venture is operated through Argentine subsidiary Sales de Jujuy SA (SDJ SA). The effective Olaroz Project equity interest is Orocobre 66.5%, TTC 25.0% and JEMSE 8.5%.

Construction Update

The construction of the project continues to proceed on time and within budget and a total of approximately $194m has been spent or committed via executed contracts in the construction project. In terms of physical progress the construction program is approximately 85% complete.

Since the last quarterly report, the Company announced the commissioning of the liming plant which allowed the removal of magnesium from the brine to commence as brine is transferred from pond 4B to 4A. The gas pipeline was completed and was awaiting the branch line connection by Gas Atacama which has now been completed. The southern bore field brine duct was commissioned in February which delivers brine directly from the southern field into pond 4B from the southern field. This replaced the temporary trench system which was moving brine to the northern field intermediate pump station. Replacement transfer pumps in the southern borefield are due to be installed in May which will allow the steady state production pumping rate of approximately 180l/s to be ramped up to a peak rate of approximately 220l/s for pond filling purposes in May.

As part of the bore field development one bore was drilled to 304m, the deepest hole to date by the company in Olaroz. Pumping tests have confirmed good hydrogeological properties and a high brine grade, averaging 770 mg/l. Previous geophysical surveys by Orocobre have suggested the Olaroz salar deposits may extend to 600m.

Construction works continue on the lithium processing plant, finished goods warehouse and the soda ash warehouse.

The project implementation is through EPCM (Engineering, Procurement and Construction Management) with a high proportion of local involvement through construction and supply contracts and local employment. The unique community and shared value policy continues as a key success factor, training local people under the supervision of high quality experienced professionals.

Borax Argentina

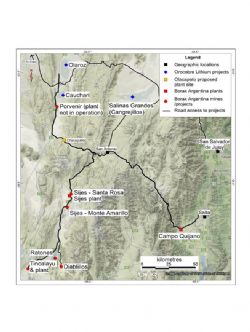

Borax Argentina has extensive operations and has a fifty year production history producing borax chemicals, boric acid and boron minerals. The production currently comes from three principal mines at Tincalayu, Sijes and Porvenir with concentrators at the first two locations and a chemicals plant at Campo Quijano producing refined products. The borax circuit at the chemicals plant is in the process of being relocated to the Tincalayu mine where the mineral for borax production, tincal, is mined.

Operations

Approximately 9,027 tonnes of combined products were sold during the quarter. This is in line with the March quarter last year and follows two quarters of record growth. The March quarter is normally a lower quarter impacted by Brazilian Carnival but sales were also impacted by inventory management required during the relocation of the Borax plant. There are signs that demand is improving with the second half of 2014 expected to show both positive demand trends and improving market prices. In spite of the challenging market conditions and the inventory management required during the plant relocation, Borax Argentina is on track to achieve or even exceed the budget for the financial year.

Combined product sales volume by quarter:

----------------------------Quarter Combined Product Sales (tonnes)----------------------------September 2012 9,161December 2012 10,007March 2013 9,182June 2013 9,562September 2013 10,103December 2013 11,410March 2014 9,027----------------------------

Boric Acid Plant Pre-Feasibility Study

In April the Company advised of the completion of a prefeasibility study into the construction of a new Boric Acid plant at Olacapato in Salta province, Argentina. The key findings are detailed below:

---------------------------------------------------------Production Rate 25,000 tpa Boric AcidCapital Cost US$ 18.2 million plus $2.6m in working capital and commissioning costs.Payback 4.9 yearsCash Operating Cost at 25,000 tpa 484 US$/tonAfter Tax NPV (10%) $17.7 millionAfter Tax IRR% 24%Modelled Project Life 20 yearsMeasured and Indicated Resources 1.02 Million tonnes B2O3-----------------------------------------------------------

The plant flow sheet will be designed to allow treatment of lower "run-of-mine" grade ores than are currently being processed and with the aim of obtaining higher recoveries and reduced operating costs. Currently, ore is mined at less than 20% B2O3 and upgraded by hand methods and screening to 26% for cartage to Campo Quijano.

Given the positive outcome of the prefeasibility study, the project will be advanced to the next stage with Feasibility Study level studies in mining engineering to produce an ore reserve and life of mine plan and detailed engineering level on the plant as the previous level of work had already been within a +/- 15% accuracy. This will occur at the same time as permitting and will allow an investment decision to be made towards the end of 2014.

Currently, Borax Argentina produces boric acid from a 9,000 tonnes per annum plant at Campo Quijano near Salta city, processing ulexite mineralisation mined from Porvenir which is located 300kms away. The plant is designed to treat a high grade feed of ulexite mineralisation which has been selectively mined and then upgraded by drying and hand sorting.

There are potential advantages to the construction of a new and larger facility at Olacapato. In particular, by being able to process lower grade "run-of-mine" ore the costly and time consuming process of drying and hand sorting would be eliminated and the mining and processing recovery of mineralisation increased. In addition, the long cartage by road transport would be eliminated and the increased production rate would provide economies of scale compared to current operations.

Boric acid is used in a wide variety of applications including glass, ceramics, fertilisers and wood preservatives. The market has a growth profile above world GDP growth. For standard and agricultural grade boric acid, pricing has ranged approximately between US$750/t to $1,250/t CIF over the past 5 years.

Borax Plant Relocation

The Company is nearing completion of the project to relocate the borax chemical plant from Campo Quijano to the Tincalayu mine where the mineral, tincal, used to make borax is mined. The Borax Argentina chemical plant produces borax decahydrate, borax pentahydrate and anhydrous borax.

The relocation of the borax plant to the Tincalyu mine site will have significant benefits through both the reduction of operating unit costs and also increasing overall mineral recovery from the mine.

The Company provided an update on the project's progress in March. Currently, the project is running on schedule and within budget. The target completion date for the project was forecast to be June 2014. It appears it may possibly be completed ahead of schedule. The Company considers this project an exciting development which will position the Borax Argentina business well for the future.

Historical Estimate for JORC Compliant Resource Conversion Programme

Porvenir

In April, the Company announced the upgrade of a historical estimate to a Measured and Indicated Resource for the Porvenir borate deposit in Jujuy Province, Argentina.

The highlights are:

- Measured and Indicated Resource of 2.3 million tonnes at 20.4% B2O3 is estimated at the current 16% B2O3 mining cut-off grade.

- Resource estimate in line with superseded historical estimate at the same cut-off.

- The resource extends to a maximum depth of approximately 3 m and is easily exploited by low cost strip mining.

- A Measured and Indicated resource of 6.9 million tonnes of 14.9 % B2O3 is estimated at a 9% B2O3 cut-off, a value appropriate for processing of the mineralisation at a potential new boric acid plant at Olacapato.

The Measured and Indicated Resources are detailed in the table below:

-----------------------------------------------------Classification Cut-off Grade Tonnes grade Tonnes % B2O3 B2O3-----------------------------------------------------Measured 16% 1,474,341 20.0 295,117Indicated 16% 804,595 21.0 168,776Measured & Indicated* 16% 2,278,937 20.4 463,992----------------------------------------------------------------------------------------------------------Classification Cut-off Grade Tonnes grade Tonnes % B2O3 B2O3-----------------------------------------------------Measured 9% 4,907,877 14.5 710,672Indicated 9% 1,942,433 16.0 310,517Measured & Indicated 9% 6,850,000 14.9 1,020,000-----------------------------------------------------

This compares to a superseded historical estimate of 2,417,099 tonnes at 20.2% B2O3 calculated at a cut-off between 14% and 19% B2O3, depending on the mineralisation style. The superseded historical estimate was originally reported on the 21st of August 2012, at the time of the announcement of the Company's purchase of Borax Argentina. The majority of the ulexite is hosted within a sand matrix, which is easily separated from the ulexite by screening after drying. The screened ulexite from this mining operation is then available for processing into boric acid.

Other deposits

The company is in the process of upgrading the historical estimates of the different Borax Argentina mining properties to JORC/NI43-101 compliant mineral resources. The Porvenir resource estimate, calculated in accordance with the requirements of JORC 2012, is the first re-evaluation of the Company's borate resource base. Geological interpretation and re-estimation of the resources at the Diablillos and Tincalayu projects is currently underway. Once completed, the focus will move to the tertiary Sijes hydroboracite deposit. The historical estimate (now superseded) of the Porvenir deposit was only a small part (14% of contained B2O3) of the overall quantum of the historical estimates of the mineralisation on Borax Argentina properties. For more information on Borax Argentina

Corporate and Administration

SAP Implementation

An SAP ERP system has been implemented at Sales de Jujuy SA and at Borax Argentina SA. System refinements are now in progress.

Cash Position

At the end of the quarter, the company had a cash position of A$28.7m excluding funds in Olaroz Lithium Project companies.

To view figures, tables and diagrams, please visit:

http://media.abnnewswire.net/media/en/docs/ASX-ORE-795119.pdf

About Orocobre Limited

Orocobre Limited is listed on the Australian Securities Exchange and Toronto Stock Exchange (

Orocobre Limited is listed on the Australian Securities Exchange and Toronto Stock Exchange ( ASX:ORE) (

ASX:ORE) ( TSE:ORL) (OTCMKTS:OROCF), and is building a substantial Argentine based industrial chemicals company through its portfolio of lithium, potash and boron assets. In partnership with Toyota Tsusho Corporation (TTC) and JEMSE, Orocobre has built and is now operating the world's first commercial, brine-based lithium operation constructed in approximately 20 years.

TSE:ORL) (OTCMKTS:OROCF), and is building a substantial Argentine based industrial chemicals company through its portfolio of lithium, potash and boron assets. In partnership with Toyota Tsusho Corporation (TTC) and JEMSE, Orocobre has built and is now operating the world's first commercial, brine-based lithium operation constructed in approximately 20 years.

In 2018 Orocobre announced the Stage 2 Expansion of its flagship Olaroz Lithium Facility in Argentina. The Stage 2 Expansion will add 25,000 tpa of lithium carbonate production capacity, taking full production and capacity to 42,500 tpa of lithium carbonate for sale to industrial, technical and battery markets, positioning Orocobre as one of the world's largest and lowest cost lithium chemicals producers.

Additionally, Orocobre and Toyota Tsusho Corporation have commenced construction of the 10,000 tpa lithium hydroxide plant in Naraha, Japan. The construction of the Naraha Lithium Hydroxide Plant will further cement Orocobre's position as a global lithium chemicals producer operating at the bottom quartile of the lithium cost curve. This new hydroxide plant will be the first of its kind in Japan and will provide Orocobre product diversification suitable for different battery technologies and the potential for significant margin growth on our primary lithium carbonate being converted to battery grade lithium hydroxide.

| ||

|