From Australia to the UK, LUYTEN's 'Platypus' printers are the preferred choice, and meet the highest standards required for tertiary research.

MELBOURNE , VIC , AUSTRALIA, January 9, 2025 /EINPresswire.com/ -- LUYTEN is celebrating partnerships with UNSW, Swinburne University of Technology, and recent sales of its 200kg construction, 3D printers to Northumbria University in the United Kingdom, as well as printer sales to the University of Western Sydney, University of Southern Queensland, and Griffith University on the Gold Coast.Northumbria University:

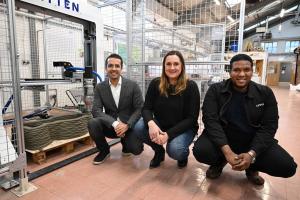

Last month, Northumbria University in Newcastle, U.K, was thrilled to receive and install LUYTEN’s cutting-edge construction printer for its Construction Engineering Department.

The University’s search for a construction printer went global, but the Melbourne manufacturer LUYTEN was the first choice.

The purchase was made possible through a British Royal Society research grant.

Northumbria’s Assistant Professor of Structural Engineering, Dr Mohammadali Rezazadeh, said, “our team is leading research in 3D concrete printing technology to develop sustainable infrastructure.

‚ÄúWe are proud to collaborate with LUYTEN, a world-leading 3D construction printer manufacturer, LUYTN‚Äôs ‚ÄėPlatypus X‚Äô concrete printer can produce complex geometrical structures in a short amount of time, using biomimicry to create better weight-to-strength ratios with less concrete.‚ÄĚ

LUYTEN’s President and CEO Ahmed Mahil said, “Northumbria University is among the first LUYTEN construction 3D printers to arrive in the United Kingdom.

‚ÄúOur printers are the fastest-selling construction robots worldwide and we look forward to seeing how they can address challenges in the UK, especially in the housing industry,‚ÄĚ Mr Mahil said.

University of Southern Queensland:

Recently LUYTEN‚Äôs Mr Mahil presided over the commissioning of a cutting-edge, giant ‚ÄėPlatypus‚Äô construction printer at the University of Southern Queensland School of Engineering in Brisbane.

Dr Saya Ramakrishnan and his team of researchers and students will use the printer to break new ground in digital construction, concrete 3D printing, sustainable construction materials, and concrete development.

This collaboration highlights LUYTEN's key role as a technology enabler in instigating research that will revolutionise the building and construction industry.

Swinburne University of Technology:

LUYTEN is excited to announce a new research and development partnership with Swinburne University of Technology.

Swinburne won a prestigious Australian Research Council grant to use earth materials, and mud for 3D printing over a three-year period.

The partnership with LUYTEN demonstrates a mutual commitment to maintaining a science-based approach to the development and implementation of construction 3d printing, using sustainable earth materials to transform affordable building solutions.

Dr Mohamed Gomaa and his team at Swinburne’s School of Design and Architecture and the School of Engineering will be leading the research activities focusing on integrating digital design and manufacturing techniques with earth-based materials such as cob and rammed earth, with a special interest in additive manufacturing and on-site 3D printing systems.

Western Sydney University:

Western Sydney University’s Urban Transformations Research Centre addresses one of the greatest challenges facing humankind: how to transform our communities and infrastructure into sustainable, equitable, and regenerative futures.

In 2024 Prof. Sarah Zhang and Prof. Richard (Chunhui) Yang from the Centre purchased a 3D Construction Printer from LUYTEN 3D.

PhD student Mahfuzur Rahman and Research Fellow Dr Sanket Rawat used the printer to spearhead research on 3D printable cementitious composites and the development of green and durable fire-resistant cementitious composites which were featured in the Centre’s research on sustainable construction and infrastructure resilience.

About LUYTEN:

LUYTEN’s cutting-edge 3D printer technology enables builders to transform construction projects that would traditionally take months or years to complete and instead finish them within a number of days.

The 3D concrete printing revolutionary technology enables 60 percent reduction of construction waste, 70 percent reduction of production time, and 80 percent reduction of labour costs when compared to hands-on construction projects.

Ahmed Mahil

LUYTEN

433 881 920

email us here

Visit us on social media:

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.