ArtiMinds and LMI will be showcasing advanced robotic automation solutions for sensor-based cable assembly as well as new ways for process data analysis.

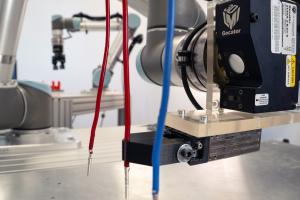

The presented solution demonstrates the detection, picking and joining of flexible cables in connector housings. One of the most important innovations is the integration of the Gocator line profile sensors from LMI Technologies, which are now fully supported by the ArtiMinds Robot Programming Suite (RPS). This extension enables even more precise and robust detection of the cable position in order to efficiently automate complex robot applications with multidimensional image acquisition. “By supporting the LMI Gocator laser scanner series, we are expanding the flexibility of our software and offering our customers the opportunity to integrate a wide range of advanced sensor technologies into their automation solutions,” explains Dr. Sven Schmidt-Rohr, Managing Director of ArtiMinds Robotics.

Focus on process data analysis

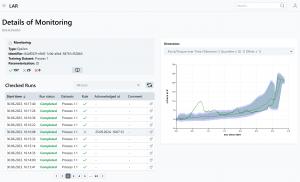

In addition to the cable handling demonstration, ArtiMinds Robotics will be focusing on process data analysis using the ArtiMinds Learning & Analytics for Robots (LAR) software solution at SPS. This makes it possible to automatically record and visually evaluate sensor data such as force measurements. This allows to precisely identify process deviations or reasons for faulty insertion processes.

Another highlight is the ability to centrally store camera data such as images from the SensoPart vision sensor used in the demo and link it directly to the respective process step. Standardized interfaces to industrial components and OPC UA ensure simple integration without additional programming effort and also enable the analysis software to be installed in already existing systems. This opens up new ways of monitoring and recording automation processes plant-wide in real time without having to focus on robot data only. “With ArtiMinds LAR, we not only offer our customers the ability to automatically record process data, but also the option to save this data over a longer period of time for documentation purposes. This allows to analyze production processes retrospectively, identify causes of errors such as wear or different product batches and make important optimizations,” adds Schmidt-Rohr.

Robotics software for versatile and flexible automation

ArtiMinds RPS makes it easy to create highly adaptive and sophisticated robot programs that can be executed directly on the industrial robot's standard controller without additional hardware. The software thus covers a wide range of applications - from simple pick-and-place processes to complex sensor-based assembly operations.

“Taking part in the SPS trade fair is an ideal opportunity for us to present the latest innovations in robot-based automation to a broad specialist audience and to show how our software solutions can help companies to make their production processes more flexible and efficient,” summarizes Schmidt-Rohr.

Silke Glasstetter

ArtiMinds Robotics GmbH

contact@artiminds.com

+49 721 5099980

Visit us on social media:

Facebook

X

LinkedIn

YouTube

Advanced Robot Applications powered by ArtiMinds

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.