Inventor says AI enables unique paper thin shape sensors, soft robots, and using thinner stronger metals to reduce vehicle weight and fight climate change.

SANTA FE, NM, USA, April 9, 2024 /EINPresswire.com/ -- The website bistabledome.com describes how very shallow flex actuated overlapping bistable domes, or OBDs, can be used to create unique low cost paper thin shape digitizing sensors for soft robots, prosthetics, rehabilitation, sports training, and more. OBDs can also be used to stiffen and shape thin high strength metals to reduce vehicle weight, increase fuel efficiency, and fight climate change.

Two patents were granted to Paul Ericson for the shape sensor and a simple pump that pumps when bent. The website bistabledome.com explains those OBD applications and how they can also be used to stiffen and shape thin strong metals.

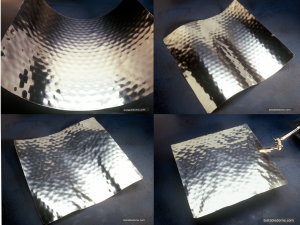

“Flex actuated overlapping bistable domes are very shallow and formed in thin high strength steel. They create structures that are considerably stiffer than the original material but only 2 or 3 times as thick in profile” says Ericson. “When bent OBD behavior can be used to monitor shape and changing shape.”

“One bistable dome is a very simple structure but overlapping interconnected rows and arrays get complicated. AI can help develop OBD applications with pattern recognition, predictive modeling, simulation and experimentation, rapid prototyping, and material research. And OBD products will expand uses for AI.”

The short video below demonstrates OBD behavior in rows and arrays.

According to Ericson OBDs can be turned into on/off contact switches with paper thin flex circuitry. When kept parallel to a stiffer flexible surface a row of OBD switches becomes a bend or 2D shape sensor capable of indicating where, how much, and in which direction from flat the surface is deformed, regardless of its position in space.

“Multiple rows or grids of 2D OBD sensors can produce 3D shape information in digital form. AI is a perfect tool for using digital OBD patterns for object identification and measuring curvature, displacement, impact, force, motion, pressure, timing, position, weight, and fluid motion, for instance,” says Ericson.

Low resolution 2D and 3D sensor prototypes are demonstrated at the bistabledome.com website.

The website suggests applications include softer, safer robots, smart tires and safety bumpers, measuring pressure and positioning for advancing prosthetics, rehabilitation and gait analysis tools, car seat sensors for triggering airbags, athletic and sports training tools, and more. “OBD sensors can also complement and help calibrate remote sensing and open possibilities where remote sensing is impractical or impossible,” claims Ericson.

Stiffening and shaping thin high strength metals:

According to the website arrays of equally bistable OBDs can stabilize in a wide range of shape, within minimum radius limits. OBDs with a bias for one side can be used to force flat materials into desired shape, from simple tubing to 3D shape. “AI will make it much easier and faster to design and manufacture OBD arrays, which may be well suited for the gentle curves common in transportation related applications,” says Ericson.

According to Ericson OBD array stamping pressure is relatively low for high strength materials because they are stamped incrementally and distortion is incorporated in surrounding OBDs. That makes it possible for common 3D printing materials to be used for tooling, speeding up prototyping and development.

Ericson believes an impact printer stamping OBDs of different characteristics could produce a wide range of curvature and shape and reduce tooling requirements. For large scale production rollers can also be used. OBD structures can be produced and stored in a flattened form until released to take their intended stable shape.

According to the website coatings and glues can be used to lock OBD orientation to increase stiffness and control flexibility and deflection. “Laminates of OBD layers can be very strong for their weight and could help reduce structural framing for vehicles, boats, containers, etc.,” says Ericson. “The SpaceX Starship could use thinner OBD layers that would add strength while reducing weight and framing requirements, for instance.”

A pump that pumps when bent:

OBD pumps are very simple and made with a single OBD or a row of OBDs, a flexible housing, and check valves. They can be made in a wide range of scale and utilize natural or mechanical motion to pump. Ericson believes large OBD pumps can use water motion for erosion control, remove unwanted sediment, pump cool water over corals, and possibly desalinate saltwater.

For more information visit bistabledome.com.

Paul Ericson

bistabledome.com

email us here

Behavior of rows and arrays of flex actuated overlapping bistable domes (OBDs) demonstrated. OBD pumps demonstrated at end of video.