Ionic Technologies advancing wind turbine recycling activity

Melbourne, Mar 14, 2024 AEST (ABN Newswire) - Ionic Rare Earths Limited ( ASX:IXR) (

ASX:IXR) ( IXRRF:OTCMKTS) is rapidly assembling a secure and sustainable Western supply chain for the renewable energy industry. The Company is in line to become the next ASX-listed magnet rare earth oxides (REOs) producer, and the first major producer of recycled separated magnet REO in the Western world, following the completion of process commissioning at Ionic Technologies' Belfast, Northern Ireland magnet recycling plant.

IXRRF:OTCMKTS) is rapidly assembling a secure and sustainable Western supply chain for the renewable energy industry. The Company is in line to become the next ASX-listed magnet rare earth oxides (REOs) producer, and the first major producer of recycled separated magnet REO in the Western world, following the completion of process commissioning at Ionic Technologies' Belfast, Northern Ireland magnet recycling plant.

- Ionic Technologies' rapidly developing sustainable and secure Western supply chain, with Company set to become next ASX-listed magnet Rare Earth Oxide (REO) producer;

- Ionic Technologies' Belfast Demonstration Plant progresses magnet REO production from wind turbine magnet recycling program;

- In 2023, European wind farms saw 736 MW of wind power decommissioned across nine countries;

- Permanent magnet recycling from the rapidly growing EU wind turbine decommissioning and repowering forecast to see five-fold rise by 2030; and

- 5 tonnes of decommissioned wind turbine permanent magnets processed through crushing, grinding circuits and digestion circuits; NdPr/DyHo separation to commence, following successful production of mixed REO products.

A wholly owned subsidiary, Ionic Technologies is a global first mover in the recycling of NeodymiumIron-Boron (NdFeB) permanent magnets to high purity separated magnet REOs - enabling the creation of sustainable, traceable, and sovereign rare earth supply chains.

During 2023, Ionic Technologies constructed a magnet recycling Demonstration Plant and produced quantities of high purity (> 99.5%) neodymium (Nd) and dysprosium (Dy) rare earth oxides (REOs) (ASX 19 June 2023).

Ionic Technologies has now commenced operations processing of end of life (EOL) permanent magnets from a decommissioned wind turbine generator. To date, five tonnes of permanent magnets from the seven-tonne magnet, have been processed to intermediate REE products. Process commissioning of both digestion and oxalation stages has been finalised, and these circuits have been used to produce batches of mixed REO products. pH adjustment and feed preparation for the mixer-settler separation stages of this production run are underway.

The first production run features NdPr/DyHo separation, from which the target will be to produce high purity NdPr oxide, plus separated Dy oxide and Ho oxide (holmium). High purity NdPr oxide and Dy oxide will then be passed on to partners under the collaboration agreement with Less Common Metals (LCM) and Ford (ASX 12th September 2023) to develop a traceable, circular supply chain of rare earths for application in EV motors within the UK.

Ionic Rare Earths' Executive Chairman, Mr Brett Lynch, commented:

"This is a major step forward in the development of an ex-China supply chain, with IonicRE offering the potential to become the first and only REO recycler from wind turbine magnets in the Western world.

"The size of the prize is significant, given the tremendous rate of growth in the wind turbine market, particularly given our proximity to the UK and Northern Ireland wind farms market with the Port of Belfast on our doorstep. With over 3,000 wind turbines located across the island of Ireland, the opportunity is compelling.

"IonicRE offers a clean and green process that is leading the way through innovative technology to deliver a secure supply chain for the Western world, underpinning the wind farm industry and other renewable energy sectors critical to global decarbonisation."

The Company's location in Belfast, where the harbour infrastructure will play a key role in UK offshore wind capacity roll out, and the Windsor Framework benefiting Northern Ireland's opportunity with immediate access to European markets provides IonicRE with a unique exposure to this market.

Significant progress has been made to deliver the Demonstration Plant and produce high purity REOs, from end-of-life permanent magnets and magnet production waste streams throughout the supply chain.

Notably, the variability in the REE composition in end-of-life permanent magnets can result in significant variability in the products produced by other recycling technologies. IonicRE's offering can accommodate this variability, plus other feed stream such as swarf from rare earth metals, alloy and magnet manufacturing, enabling consistent high purity REO products of recycled origin, another unique selling point for the technology.

IonicRE is also working with a number of new potential partners to evaluate alternative feed streams to satisfying demand for production campaigns.

Wind Turbine Recycling Potential

Wind farms have a finite operational lifetime, typically ranging from 15 to 25 years, after which they are decommissioned. An alternative common in Europe is a process called repowering where operators replace smaller, less efficient turbines with larger, modern turbines with increased capacity, even with fewer new turbines. This increased capacity is known as repowered capacity Wind farm repowering typically trebles its output on average, while also reducing the number of turbines on operation. For this reason, it presents a unique opportunity to quickly ramp-up wind energy production in Europe.

IonicRE has been engaging with European wind farm operators, and OEMs (original equipment manufacturers) to help position the Company and the technology at the forefront of the emerging recycling opportunity across both permanent magnets sourced from decommissioned and repowering streams. As the European wind turbine fleet ages, supported by government incentives, the amount of repowering is expected to increase increasing access to more magnets beyond the decommissioning profile.

In 2023, European wind farms saw 736 MW of wind power across nine countries was decommissioned, and 1.4 GW of new capacity came from repowering projects (see Figure 1*).

A recent report from Wind Europe1 indicated a significant proportion of European onshore wind farms are approaching the end of their planned operational lifetime. Currently, 22 GW of Europe's existing wind farms have already been running for more than 20 years. By 2030, 52 GW of capacity will be more than 20 years old, and it is expected that almost all repowered capacity by 2030 will come from onshore wind.

Over the next seven years Wind Europe forecasts expect annual decommissioned capacity to increase seven-fold to 5.2 GW, along with a more than three-fold increase in repowering to 5.0 GW as illustrated in Figure 2*.

The cumulative expectation for decommissioned wind farms is estimated at approximately 27 GW between now and 2030, representing a substantial base load for the development of magnet recycling from existing wind turbine capacity.

Typically, each MW of wind turbine capacity, if using permanent magnet direct drive generators, can include up to 600 kg of permanent magnets. IonicRE is working with wind farm operators and OEMs to understand the market opportunities. It should be noted that the existing wind turbine fleet includes both turbines using direct drive permanent magnets and geared drives which do not use permanent magnets.

As not all projects are repowered, the annual repowered project capacity tends not to exceed the decommissioned amount, as the proportion of projects which are repowered varies considerably by region and the policies which govern repowering, and the capacity repowered each year arises from the repowering of projects in previous years.

Mr Lynch added: "Since joining IonicRE in January and undertaking my first visit to the Company's operations, including Belfast, I've rapidly gained an understanding of the size of market opportunity for IonicRE.

"It's clear that the commercial potential for magnet recycling is developing rapidly, and IonicRE is at the forefront of realising this opportunity through its sustainable, traceable innovative technology.

"We are now in a position to capitalise on our first mover advantage, developing a sustainable business that delivers growth in shareholder value while supporting important global policy goals such as net zero emissions.

*To view tables and figures, please visit:

https://abnnewswire.net/lnk/3RHC1X19

About Ionic Rare Earths Limited

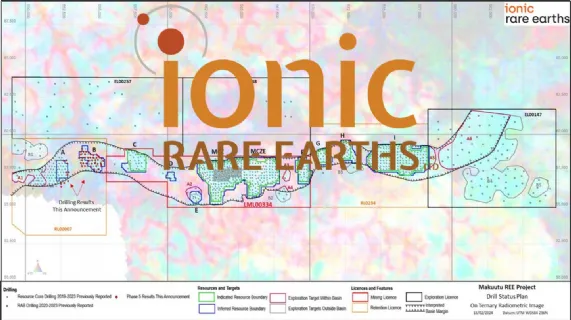

Ionic Rare Earths Limited (ASX:IXR) (OTCMKTS:IXRRF) is focused on developing its flagship Makuutu Rare Earths Project in Uganda into a significant long life, low-cost, supplier of high-value critical and heavy rare earths.

Ionic Rare Earths Limited (ASX:IXR) (OTCMKTS:IXRRF) is focused on developing its flagship Makuutu Rare Earths Project in Uganda into a significant long life, low-cost, supplier of high-value critical and heavy rare earths.

Makuutu is an advanced-stage, ionic adsorption clay-hosted project highlighted by near-surface mineralisation, significant exploration upside, excellent metallurgical characteristics and access to tier-one infrastructure.

The ionic adsorption clay-hosted geology at Makuutu is similar to major rare earths projects in Southern China, which are responsible for the majority of global supply of low cost heavy and critical rare earths, specifically the high value magnet metals (Dysprosium and Terbium) Heavy Rare Earths (>98% originating from ionic clays). Metallurgical testing at Makuutu has returned excellent recovery rates, which provide multiple avenues for a simple process route.

Makuutu is well-supported by tier-one existing infrastructure which includes access to major highways, roads, power, water and a professional workforce.

Rare Earths will play a critical role in the future of clean energy. Rare Earths are a key ingredient in the permanent magnets found in wind turbines and electric vehicles.

IonicRE is led by an experienced and proven team, who have the capabilities to deliver Makuutu into production and realise value for all stakeholders.

| ||

|