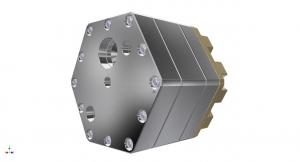

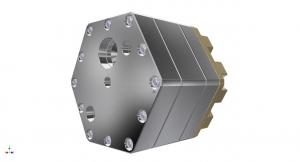

Revolutionary modular blocks featuring seamlessly extruded, intertwined anode and cathode materials, molded in a concentric formation, ready for immediate installation upon the completion of the continuous forming process.

The GigaLoomX aims to craft electrolyzers continuously by intertwining weaving, molding, extrusion, and 3D point building, employing a spectrum of materials, including metals, plastics, powder recipies, tapes, fabric, and binders.

Revolutionary modular blocks featuring seamlessly extruded, intertwined anode and cathode materials, molded in a concentric formation, ready for immediate installation upon the completion of the continuous forming process.

The GigaLoomX aims to craft electrolyzers continuously by intertwining weaving, molding, extrusion, and 3D point building, employing a spectrum of materials, including metals, plastics, powder recipies, tapes, fabric, and binders.

Giga Loom Extrusion Process: a groundbreaking blend of loom and extruder tech, transforming manufacturing with unprecedented precision and efficiency.

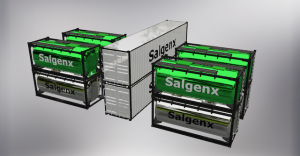

MADISON, WISCONSIN, USA, September 28, 2023 /EINPresswire.com/ -- In the rich landscape of advanced manufacturing, Salgenx and Infinity Turbine LLC introduce the Giga Loom Extrusion Process, a pioneering innovation representing the fusion of loom and extruder technologies. This revolutionary process is set to weave new paradigms in manufacturing, merging meticulous craftsmanship with precision shaping, marking a significant evolution in the realm of manufacturing technologies.

Craftsmanship and Precision: Defining the Future

The amalgamation of looms, the masters of weaving intricate textiles, and extruders, the sculptors of consistent forms, creates a harmonious dance of precision and consistency, promising a new era in manufacturing technologies and paving the way for revolutionary advancements in multi-purpose battery manufacturing.

The GigaLoomX: A Revolutionary Leap in Electrolyzer Formation

The primary use of the GigaLoomX is to continuously form electrolyzers, integral components for the Salgenx Flow Battery. The outcome is a modular block electrolyzer, meticulously crafted and ready to be installed as a cell in the Salgenx Flow Battery. These modular blocks can be easily bolted or snapped together, forming complex structures with unparalleled efficiency and precision, representing a monumental stride in battery technology.

Revolutionizing Manufacturing: Efficiency and Speed

The GigaLoomX process is poised to revolutionize traditional manufacturing methodologies, saving more than 80 manufacturing steps and reducing production time by an astounding 90 percent. This innovative synergy between loom and extruder technologies offers limitless possibilities, allowing manufacturers to explore new dimensions in production methodologies, enhancing efficiency, and offering unparalleled customization in product design and manufacturing.

Understanding the Technologies: Weaving and Shaping the Future

- Looms employ a combination of warp beams, heddles, reeds, shuttles, and treadles to create textiles that narrate tales of tradition, culture, and innovation with delicate precision.

- Extruders utilize core components and various extrusion processes to mold materials into objects with a fixed, consistent cross-sectional profile, meeting the exacting demands of diverse industries.

Innovative Synergy: Setting New Standards

This fusion is setting the stage for a future where interdisciplinary innovations redefine the boundaries of possibilities, enriching the manufacturing ecosystem and propelling it towards new horizons defined only by the bounds of imagination. It is like weaving a tapestry where each thread is a testament to human ingenuity and the pursuit of excellence, creating a mosaic of progress and innovation.

Greg Giese, CEO of Salgenx, articulates the vision behind the innovation as, "a technology which will change the way we build parts for multi-purpose batteries based on a continuous process. It’s a multidisciplinary manufacturing blend that precludes the need for robots to do assembly and other processes."

Conclusion: Harmonizing the Chords of Innovation and Progress

The convergence of loom and extruder technologies is composing the melody of the future, where meticulous craftsmanship meets precision shaping, harmonizing the chords of innovation and progress and weaving the fabric of the future of manufacturing technologies.

About Salgenx and Infinity Turbine LLC

Salgenx, in strategic collaboration with Infinity Turbine LLC, stands at the cutting edge of transformative solutions, showcasing a commitment to excellence and innovation through the Giga Loom Extrusion Process, destined to set unparalleled standards in manufacturing and battery technology.

Contact: Greg Giese | CEO | Infinity Turbine LLC | greg@infinityturbine.com | greg@salgenx.com

Infinity Turbine Website: https://www.infinityturbine.com

Saltwater Battery Website: https://salgenx.com

Gregory Giese

Infinity Turbine LLC

+1 608-238-6001

email us here