International Sapphire Industry Exhibition

Perth, July 14, 2016 AEST (ABN Newswire) - Altech Chemicals Limited (Altech/the Company) ( ASX:ATC) is pleased to provide a summary of its recent attendance at the 2nd International Sapphire Industry and Touch Screen Technology Exhibition in Shenzhen, China (June 23-25 2016).

ASX:ATC) is pleased to provide a summary of its recent attendance at the 2nd International Sapphire Industry and Touch Screen Technology Exhibition in Shenzhen, China (June 23-25 2016).

Highlights:

- Strong interest for Altech's entry into the high purity alumina market

- Altech's proposed nano particle size HPA product range well received

- Vertically integrated production model will ensure security of quality HPA supply

- Forecast tightening of supply side of the HPA market as demand rapidly expands

- HPA analytical and production data available to end-users on-line

Altech's presentation at the exhibition generated strong interest from synthetic sapphire producers, who welcome the prospect of the Company's entry into the high purity alumina (HPA) market via its proposed 4,000tpa Malaysian HPA plant. Specifically, Altech's plan to offer a finished product range that will include HPA tailored for the synthetic sapphire and lithium-ion battery separator sheet manufacturing sectors, two rapidly growing segments of the HPA market, were well received. The Company explained that the design of its Malaysian plant incorporates the specialised equipment required for the production of "nano" HPA particles. The size of HPA nano particles is typically less than 1 micron (1/1000 of 1mm) and is the preferred particle size for the fast growing lithium-ion battery separator sheet-manufacturing sector.

The Company also emphasised the vertically integrated nature of its HPA manufacturing process, explaining that unlike current HPA producers that predominantly purchase aluminium metal as feedstock, Altech by owning its own feedstock (alumina rich kaolin), is better positioned to guarantee product supply and quality to end-users into what is forecast to be a tightening HPA market. The combination of Altech's low-impurity kaolin ore feedstock and its plant's design that has incorporated three stages of purification, will position the Company to consistently deliver finished product HPA of 99.99% purity to end users, managing director Iggy Tan explained.

Another important differentiation will be Altech's ability to analyse individual one (1) tonne batches of its HPA and make production data and analytical results available to end-users on-line via its proposed internet based quality tracking system. End users advised that this type of information is not currently available from their established HPA suppliers. Also, Alech's state of the art German packaging plant can be expected to deliver highly consistent end-product bag weights for accurate product formulations and the German manufactured and supplied robotic stacking and wrapping technology will deliver neat, clean, spillage free wrapped pallets.

Mr Tan stated that with the forecast rapid increase in demand for HPA, particularly from lithium-ion battery separator manufacturers, combined with supply expansion timeframe limitations, there is a real possibility of a HPA supply squeeze in the short to medium term.

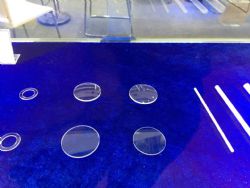

Synthetic sapphire producers at the exhibition displayed their products and technology, including the production of sapphire wafers, watch faces and smart phone sapphire display screens. Several of the established synthetic sapphire producers reported near-term capacity expansion plans and expressed interest in further discussions with Altech in relation to growth strategy.

Applications for synthetic sapphire displayed at the exhibition include luxury watches and smart watches (both cover and body), LED wafers, smart phone touch screens, camera lens covers, fingerprint recognition screens and medical optics. It was clearly evident at the exhibition that applications for the use of sapphire glass in a variety of industries continues to emerge.

To view tables and figures, please visit:

http://abnnewswire.net/lnk/BZS67W8E

About Altech Batteries Ltd

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|