Altech updated its Kaolin Mineral Resource at Meckering

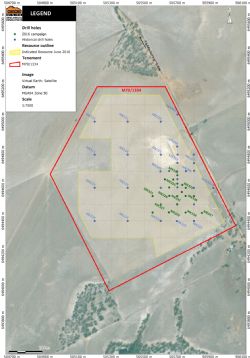

Perth, July 8, 2016 AEST (ABN Newswire) - Following the completion of grade control drilling in April 2016, Altech Chemicals Limited (Altech/the Company) ( ASX:ATC) is pleased to announce an update to kaolin mineral resources for its 100%-owned mining lease (ML) M70/1334, at Meckering Western Australia.

ASX:ATC) is pleased to announce an update to kaolin mineral resources for its 100%-owned mining lease (ML) M70/1334, at Meckering Western Australia.

Highlights

- Kaolin Indicated Mineral Resources of 11Mt @ 82.7% ISO brightness (JORC 2012)

- Sufficient resources to provide >250 years feed-stock for the Company's proposed Malaysian high purity alumina plant

- Submission of mining proposal and mine closure plan imminent

The updated Mineral Resource is 11 million tonnes (Mt) of kaolin clay containing 45% minus 45 micron clay with a brightness of 82.7% (ISO standard), and is classified as Indicated. The mineral resource was estimated using an 80% brightness cut-off, and a 30% minus 45 micron cut-off and is in accordance with JORC 2012.

At Meckering, the Company is planning to mine approximately 120,000 tonnes of kaolin once every three years in short two-month mining campaigns. The resultant raw kaolin ore will be stockpiled, then containerised into standard shipping containers at the rate of around 40,000tpa (770t per week) and transported to Johor, Malaysia via the port of Fremantle, Western Australia for processing into high purity alumina (HPA) at the Company's proposed plant.

Altech's proposed Malaysian HPA plant is designed for annual production of 4,000tpa of HPA. At this production rate there are sufficient kaolin mineral resources at Meckering for in excess of 250 years of feed-stock supply.

Altech managing director Mr Iggy Tan said, "The Company is delighted with the updated mineral resources statement for our recently granted ML.

"Altech can now progress to the next stage in preparation for mine development, the submission of what will be a relatively straightforward mining proposal and mine closure plan.

"Upon approval of these items, the site at Meckering will be ready for the development of the campaign mining and container loading operation to supply feedstock for Altech's proposed Malaysian HPA plant.

"This marks another significant milestone in the advancement of the Company's HPA project", Mr Tan concluded.

Mining Lease M70/1334

The Company's granted tenement M70/1334 covers 86Ha of freehold land situated adjacent to the town of Meckering, approximately 130km from Perth, Western Australia. The ML is held by the Company's wholly-owned subsidiary Altech Meckering Pty Ltd and hosts the Meckering kaolin deposit.

Meckering Resource Estimation

An Indicated Resource of 11MT, containing 45% minus 45 micron clay with a brightness of 82.7% (ISO standard).

The resource was estimated using an 80% brightness cut-off, and a 30% minus 45 micron cut-off.

The minus 45 fraction has been demonstrated by extensive testwork, including pilot plant production, to be suitable for production of high quality kaolin for use as paper filler, or in paint or ceramic industries, with potential for production of some paper coating clay product.

The resource has been trimmed to 40m below surface and to 40m inside the mining lease boundaries, and commences below the laterite zone, generally 5 to 8m below surface. There are occasional minor lenses of low brightness clay within the resource outline, but the resource is otherwise a continuous sheet, 5 to 35 m thick, within the outline shown on the map.

Altech has conducted tests on a bulk sample which demonstrated suitability of this material for economic production of high purity alumina. Altech intend to use a minus 500 micron fraction as feed into this process, to lower the amount of silica in the feed. The minus 500 micron fraction is expected to be 60% to 70% of the mined material, and this fraction is expected to contain 18% to 23% alumina.

Geology

The kaolinite is a residual weathering product of granite and granitic-gneiss of the Western Gneiss Terrane. Kaolin in this region is related to in-situ lateritic weathering of predominantly granitic rocks, with kaolin has developed in the pallid zone below a laterite and overlies weathered granite.

Minerals identified by XRD analysis of two cores from within the kaolin deposit include: quartz, kaolinite, smectite, micas (muscovite + biotite), chlorite, orthoclase, goethite and magnetite. Quartz is present throughout the full deposit profile in varying quantities.

Drill hole data and bulk sample data to date all confirm the type model for the deposit.

Sampling

Several periods of drilling have been conducted by different companies since the 1990s to present. These were CRA Exploration Pty Ltd (CRAE) in the 1990s, Minerals Corporation Ltd subsidiary and Swan River kaolin (SRK) from 2003 to 2010, and recently Altech Chemicals Limited in March 2016.

In total 49 vertical RC (reverse circulation air core) drill holes are located within Mining Lease M70/1334, including 19 from the 2016 campaign. All drilling has been conducted using standard wireline drilling techniques. Drill holes within the Mining Lease are spaced from 30 to 200m apart. Drill hole collar information is tabulated in Appendix 2 and recorded drill hole intersections are tabulated in Appendix 3.

From the RC drilling 1 m down hole interval samples were obtained and retained. If the sample was white, off white or pale cream the sample was retained in full for despatch to the laboratory.

Sample sizes are considered appropriate to the grain size of the material being sampled. No subsampling was conducted at drill site.

A total of 1,546 samples were collated in the database; this included samples from historic drilling surrounding the mining lease. A total of 669 1m samples were collected from the 2016 drilling.

Due to the nature of the drilling method and considering the full sample intervals collected for analysis, recoveries were not recorded. Drill samples have been disturbed by the drilling process and hence may include some minor contamination and hence the quantitative analysis may inherit some minor error. The level of any sample bias or inherent sample error is considered to be minimal.

All RC drill chip and spoils from drill holes were geologically logged on a meter interval basis. The colour and brightness were especially noted. During the 2016 campaign a Munsell soil colour chart was used for comparison of spoil and chip colour and brightness logging.

Hand held GPS was used to locate drill hole positions. Drill hole positions were later surveyed.

Modelling

Random data checks were made to original SRK lab sheets and with available CRA data. 2016 data from Nagrom was transferred digitally into the database. Sample data audits and reviews were undertaken during data entry into a database and further on querying during later modelling.

A block model of dimensions of 50 by 50m by 5m was used in Micromine, with interpolation by ordinary kriging.

Interpolation has been limited to the boundary of logged kaolin. Variography on brightness and yield confirms confidence in extrapolation distance.

Ore moisture ranged between 2% and 17% with average moisture of around 13% for 2016 drilling. Moisture was recorded for the majority of samples however due to sample handling/transport issues the moisture results are considered potentially in error for the historic holes, but 2016 moisture results are considered to represent in situ moisture. Resource tonnage has been estimated on a dry basis.

Dry bulk density was calculated using downhole geophysics results from 5 holes of the 2016 campaign to get in situ wet density, and lab measured moistures from 2016 drilling. Average of short spaced density and long spaced density used. The average calculated dry density of 1.57 g/cm3 is close to the dry density of 1.6 g/cm3 assumed in previous resource estimates.

The resource model is consistent with previous estimates.

To view figures, please visit:

http://abnnewswire.net/lnk/69028669

About Altech Batteries Ltd

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|