Forecast Surge in High Purity Alumina Demand Driven by Lithium-ion Batteries

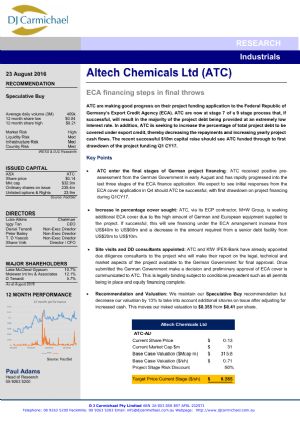

Perth, June 21, 2016 AEST (ABN Newswire) - Following its 3 June 2016 announcement regarding the strong interest shown in Altech Chemicals Limited (Altech/the Company) ( ASX: ATC) as an emerging high purity alumina (HPA) producer during the 12th China International Battery Fair, the Company is pleased to present its 10-year forecast of global demand for HPA used in the lithium-ion battery manufacturing sector.

ASX: ATC) as an emerging high purity alumina (HPA) producer during the 12th China International Battery Fair, the Company is pleased to present its 10-year forecast of global demand for HPA used in the lithium-ion battery manufacturing sector.

Highlights:

- HPA demand for lithium-ion battery manufacture forecast to increase at 30% per year to 2025

- Demand forecast to increase from ~1,000tpa in 2016 to ~15,000tpa in 2025

- Equivalent to four (4) of Altech's proposed HPA plants required to satisfy 2025 demand

- Electric vehicle manufacturers requiring lithium-ion batteries with HPA coated separators

The Company has estimated that demand for HPA from lithium-ion battery manufacturers will grow significantly over the next decade from forecast usage of ~1,000tpa in 2016 to ~15,000tpa in 2025; this represents annual year-on-year demand growth of approximately 30% per year. In order to meet this demand, additional HPA production capacity equivalent to four (4) of Altech's proposed 4,000tpa HPA plants in Malaysia would need to be constructed and commissioned during the forecast period, as illustrated in Figure 1, in link below.

The HPA demand forecast has been calculated based on lithium-ion battery manufacturing data recently published by Deutsche Bank. The data predicts annual global demand for lithium-ion batteries will rise from 70 gigawatt-hours (GWh) per year in 2015 to 535GWh per year by 2025 (see Figure 2, in link below). The Company has applied reported HPA usage per kilowatt-hour in lithium-ion battery separators (a vital battery component) to calculate forecast global HPA demand for the lithium-ion battery manufacturing sector.

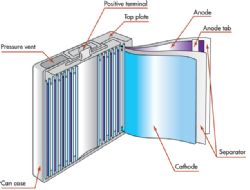

HPA and lithium-ion batteries

The major application of HPA in lithium-ion batteries is as a coating on the ceramic separator sheet that divides the cathode and anode electrodes within the battery. HPA-coated separators withstand unusually high temperature incursions, increase battery separator shrinkage temperatures and reduce flammability during thermal runaways, and thus make lithium-ion batteries much safer.

HPA-coated battery separators also increase a battery's discharge rate; lower self-discharge; and lengthen battery life cycles. Electric vehicle manufacturers are increasingly demanding lithium-ion batteries with 99.99% (4N) HPA-coated separators.

American automotive company Tesla recently announced the 2018 launch of its lithium-ion battery manufacturing facility called "Gigafactory" in the USA. The name Gigafactory comes from the factory's planned annual battery pack output capacity of 50GWh. In co-operation with Panasonic and other strategic partners, the Gigafactory will reportedly produce batteries for significantly less cost using economies of scale, innovative manufacturing, reduction of waste, and the simple optimisation of locating most manufacturing processes under one roof. Tesla expects to drive down the per kilowatt hour (kWh) cost of the battery pack by more than 30%. By 2020, the Gigafactory will reportedly reach full capacity and produce more lithium-ion batteries annually than were produced worldwide in 2013.

Altech estimates that at its full production rate the Tesla Gigafactory will require around 2,020tpa of HPA for separator coatings, which is equivalent to half the output of the Company's proposed Malaysian HPA plant.

Altech managing director Mr Iggy Tan said, "HPA demand growth in the LED sector has long been acknowledged and understood; this growth is however now complemented by HPA demand growth in the lithium-ion battery industry, specifically from battery separator sheet manufacturers.

"The timing for construction of Altech's proposed HPA plant in Malaysia appears perfect, with two parallel streams of near-term HPA demand growth now apparent. The important point is that we are entering a market showing high demand growth, Altech's proposed production capacity should be easily absorbed without the need to fight for market share", Mr Tan concluded.

To view figures, please visit:

http://abnnewswire.net/lnk/B92INO91

About Altech Batteries Ltd

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.

| ||

|